Plug Valves

What is a plug valve?

A plug valve is a kind of valve whose closing part rotates 90 degrees around the center line of the valve body to achieve the purpose of opening and closing. It is mainly used for cutting, distributing and changing the flow direction of the medium on the pipeline. According to the nature of the medium and the erosion resistance of the valve sealing surface, it can sometimes be used as a throttle.

Total 34 Records

The sealing principle of the plug valve

According to the structure of the plug valve and the material of the sealing pair, metal sealing, lubricating and non-metallic soft sealing can be adopted for the plug valve. When metal sealing is adopted, not only lower surface roughness and more accurate shape and position tolerances are required, but also higher sealing specific pressure is required to achieve the required sealing performance. When sealing with grease and non-metallic soft materials, more accurate geometry is required. According to the above requirements, there are many structural designs of the sealing pair, and the sealing principles are also different.

The characteristics of the plug valve

The plug valve has little resistance to the medium.

The plug valve has simple structure, small sizes and light weights, so it is easier to maintain.

The sealing performance of the plug valve is relatively good.

The plug valve is not restricted by the installation direction, and the flow direction of the medium can be changed.

There is no vibration in the plug valve, and the noise is reduced to a minimum.

The plug valve has simple structure, small sizes and light weights, so it is easier to maintain.

The sealing performance of the plug valve is relatively good.

The plug valve is not restricted by the installation direction, and the flow direction of the medium can be changed.

There is no vibration in the plug valve, and the noise is reduced to a minimum.

The advantages of plug valves

1. A plug valve has simple structure, few parts, small sizes and light weights.

2. The fluid resistance is small. When the medium flows through the plug valve, the fluid channel does not shrink or change the flow direction, so the fluid resistance is small.

3. The opening and closing are rapid, and the flow direction of the medium is not restricted. It is very convenient to complete the opening and closing by simply rotating at an angle of 90.

2. The fluid resistance is small. When the medium flows through the plug valve, the fluid channel does not shrink or change the flow direction, so the fluid resistance is small.

3. The opening and closing are rapid, and the flow direction of the medium is not restricted. It is very convenient to complete the opening and closing by simply rotating at an angle of 90.

Plug valves classified by structure

Cylindrical plug valves

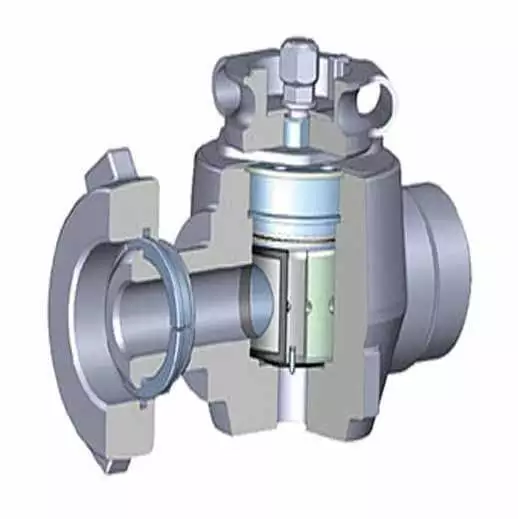

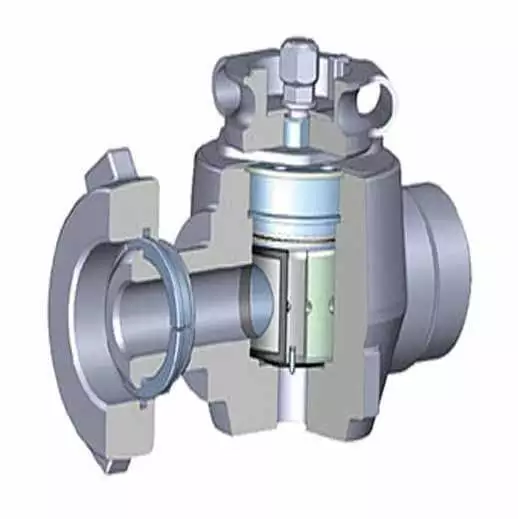

According to the sealing material, a cylindrical plug valve can be divided into soft seated cylindrical plug valves and metal seated cylindrical plug valves. Metal-sealed cylindrical plug valves are usually sealed by oil seals.

Conical plug valves

According to the sealing material, a conical plug valve can be divided into soft seated conical plug valves and metal seated conical plug valves. According to the structure, the metal-seated circular conical plug valve can be divided into the packing, oil seal, pressure balance and lifting type. According to the structural form, soft-seated conical plug valves can be divided into ferrule-type plug valves and lined plug valves.

Eccentric plug valves

The eccentric plug valve adopts an elastic seat seal structure, which overcomes the defects of poor sealing and easy corrosion of the traditional plug valve, and is widely used in urban sewage, industrial sewage, mud, clean water and other working environments, used as a flow interception or adjustment device.

Plug valves classified by sealing surface materials

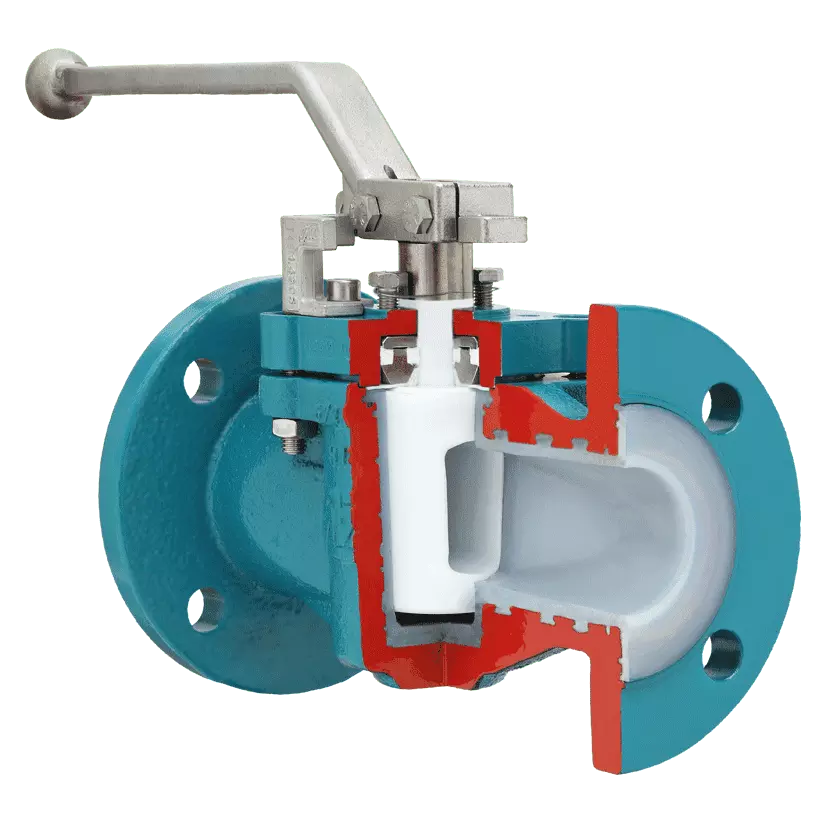

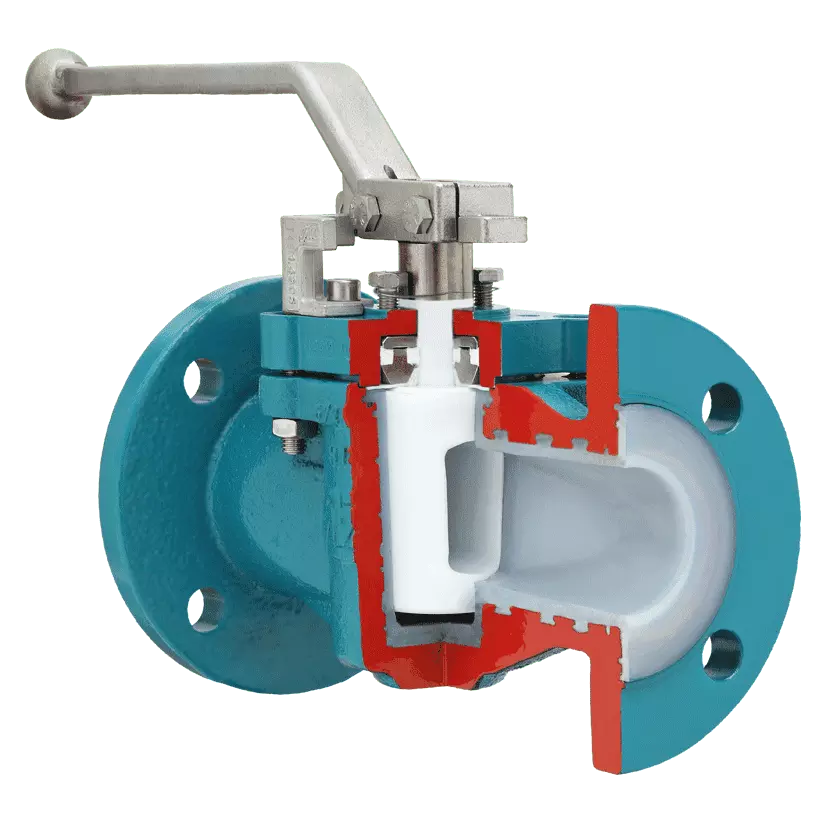

Soft-seated plug valves

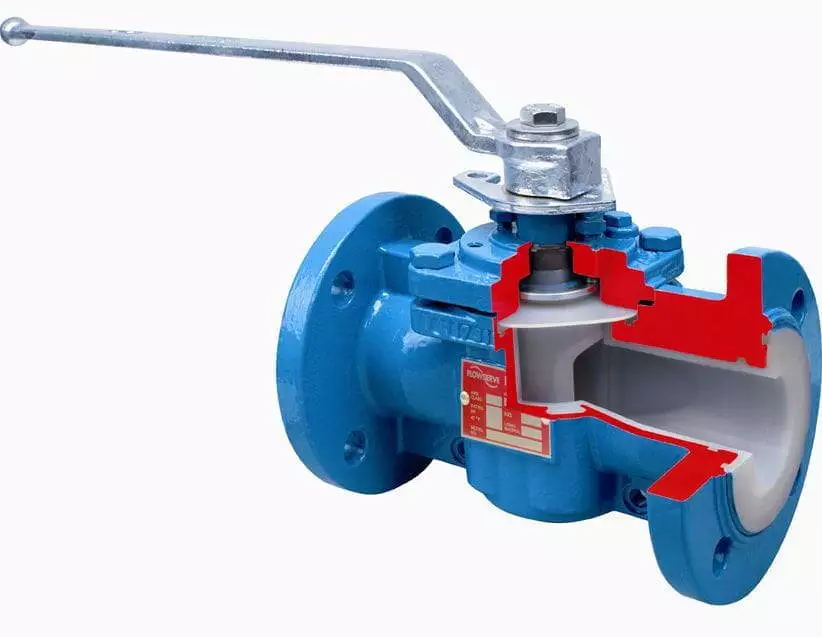

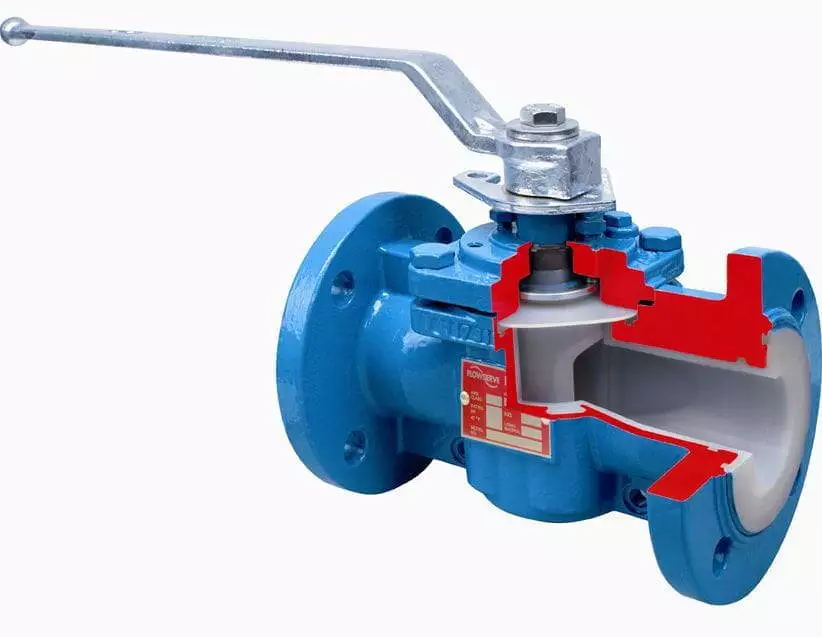

The seat between the valve body and the plug is made of soft materials, such as polytetrafluoroethylene. Soft-seated plug valves are often used in harsh environments such as corrosive, highly toxic and highly hazardous media, where the leakage is strictly prohibited, and the valve material will not pollute the medium. The valve body can be made of carbon steel, alloy steel and stainless steel according to the working medium.

Metal-seated plug valves

The valve body, the plug and the sealing surface are all made of metals.

Lubricated plug valves

A lubricated plug valve is a kind of valve sealed by oil sealing. Since the sealing surface is protected from contact with the flowing medium when it is in the fully open position, and the damaged sealing surface is easy to repair, the lubricated plug valve is especially suitable for abrasive media. However, lubricated plug valves are not suitable for throttling. The sealant will be washed from the exposed sealing surface during throttling, so that the valve body sealing must be restored whenever the valve is closed. This type of valve is suitable for branch pipes in oil fields or gas fields because this kind of pipeline does not need to be pigged, and the medium in oil fields or gas fields contains sand and water.

Lined plug valves

The leakage gap between the tapered sealing surfaces of the lined plug valve can be adjusted by the gland. When the plug is in close contact with the valve body, the plug can still be rotated, or the cock can be lifted from the valve body before rotation, rotated at an angle of 90 and then sealed to achieve zero leakage. When the plug valve is fully opened, there is no obstacle in the passage, which is especially suitable for industries such as food and medicine.

Plug valves classified by working pressure

Vacuum plug valves: the working pressure is lower than the standard atmospheric pressure.

Low-pressure plug valves: the nominal pressure is 1.6MPa or Class 150.

Medium pressure plug valves: the nominal pressure is between 2.5 to 6.4MPa or Class 150 to 400.

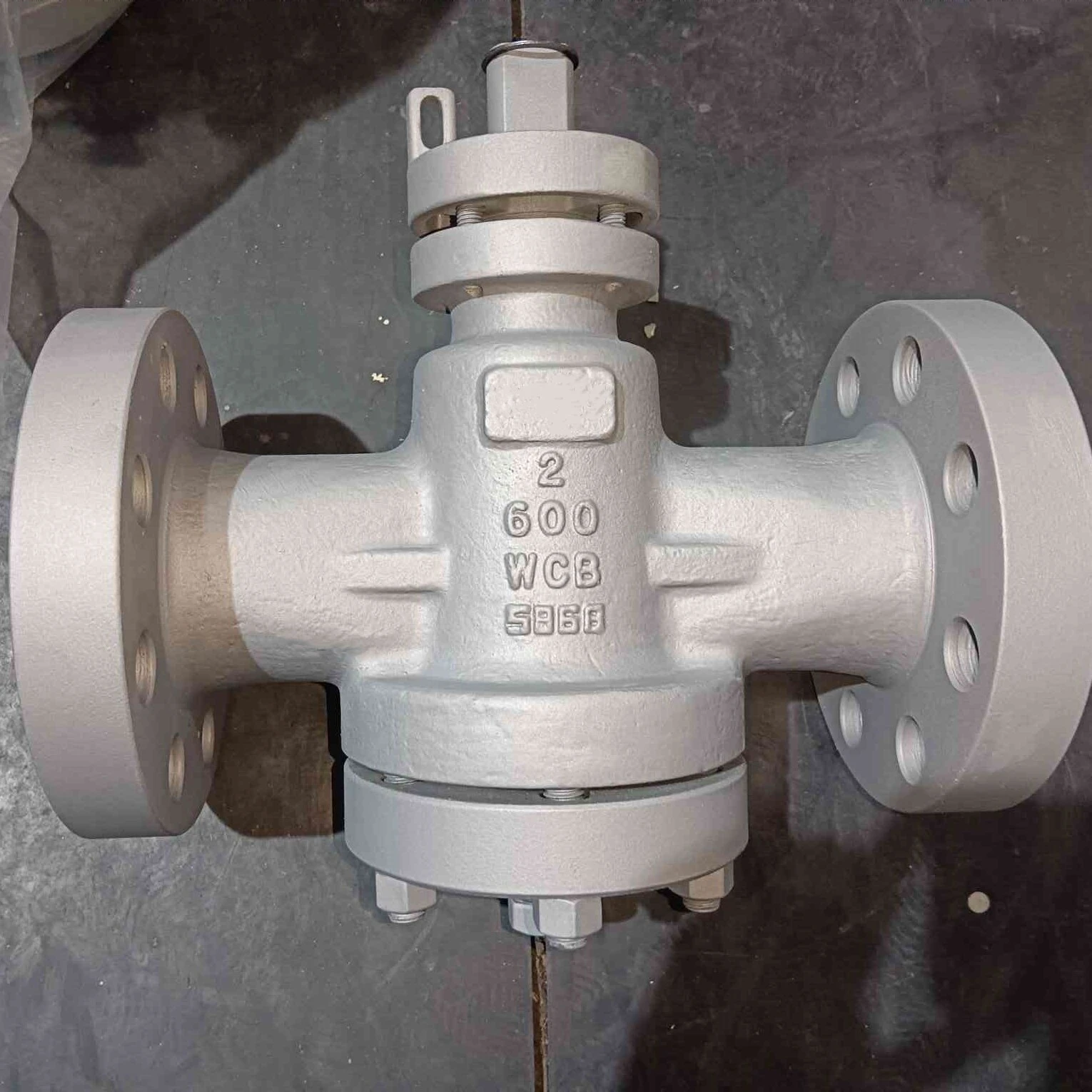

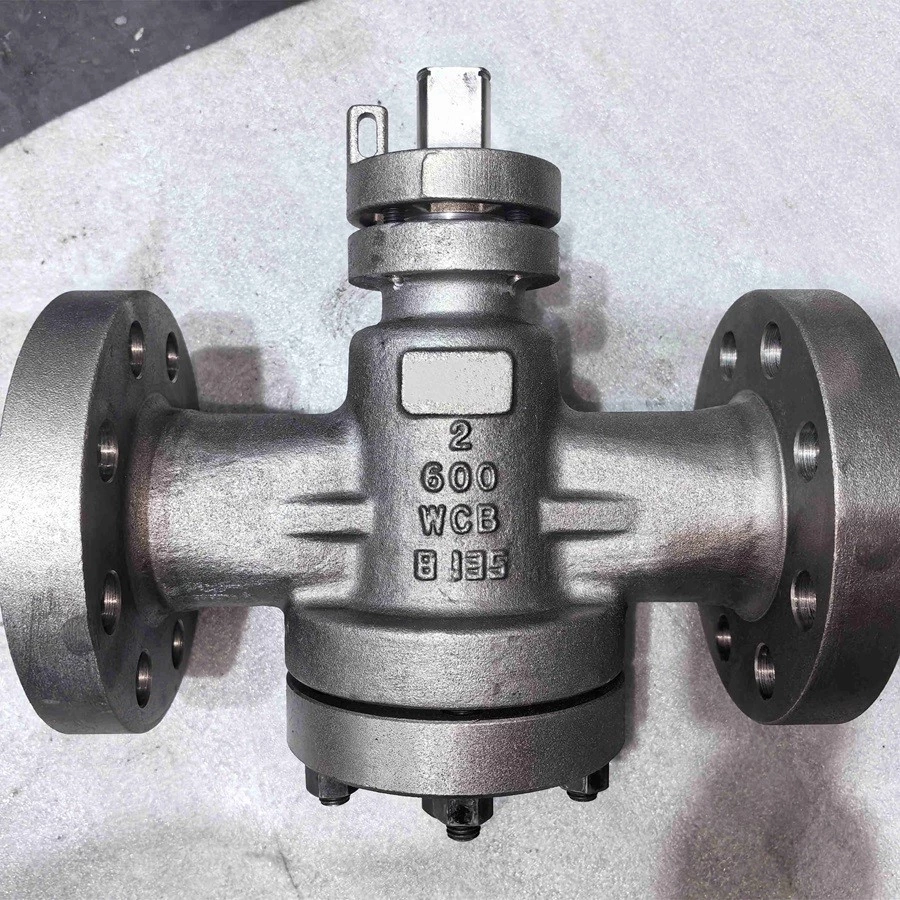

High-pressure plug valves: the nominal pressure is between 10.0 to 80.0MPa or Class 600 to 2500.

Low-pressure plug valves: the nominal pressure is 1.6MPa or Class 150.

Medium pressure plug valves: the nominal pressure is between 2.5 to 6.4MPa or Class 150 to 400.

High-pressure plug valves: the nominal pressure is between 10.0 to 80.0MPa or Class 600 to 2500.

Plug valves classified by working temperatures

High-temperature plug valves: Their working temperature is higher than 450℃.

Medium-temperature plug valves: Their working temperature is 120°C

Ultra-low temperature plug valve: Their working temperature is -100°C.

Medium-temperature plug valves: Their working temperature is 120°C

Ultra-low temperature plug valve: Their working temperature is -100°C.

Plug valves classified by connection ends

Flanged plug valves

A flanged plug valve is a kind of valve whose connection ends are flanges.

Threaded plug valves

Characteristics of threaded plug valves

They are available with female and male threads, free of cavities, maintenance-free, self-lubricating. The plug is easily adjusted, even with mounted actuators.

Welded plug valves

Design and manufacture: API and DIN standards

Nominal pressure: ANSI 150Lb to 800Lb or PN1.6 to 16.0(Mpa)

Nominal diameter: NPS 1/2-4 or DN15 to100mm

Structure length: Face to face ANSI B 16.10

Welding ends: ANSI B16.11

Pressure test: API 598

Nominal pressure: ANSI 150Lb to 800Lb or PN1.6 to 16.0(Mpa)

Nominal diameter: NPS 1/2-4 or DN15 to100mm

Structure length: Face to face ANSI B 16.10

Welding ends: ANSI B16.11

Pressure test: API 598

Ferrule plug valves

Ferrule plug valves are valves that use a plug body with a through hole as the opening and closing part, and the plug body rotates with the valve stem to realize the opening and closing action. The plug body is mostly conical, and there are also cylindrical ones. Ferrule plug valves have the characteristics of simple structure, rapid opening and closing, small flow resistance, convenient maintenance, and good sealing performance. They can be driven by handwheels, worm gear, etc., which are widely used in the system control of industrial pipelines such as chemical industry, petroleum, textile, food, pharmaceutical, medicine, and papermaking. The American standard flange ferrule plug valve is suitable for cutting or connecting pipelines in various working conditions such as petroleum, chemical, pharmaceutical, chemical fertilizer and electric power industries with nominal pressure Class 150 to 1500 and working temperature of -29 to180 ℃.

Plug valves divided by uses

Lubricated metal seated plug valves

Lubricated metal seated plug valves can be divided into conventional lubricated plug valves and pressure-balanced plug valves. Special lubricating grease is injected between the taper hole of the valve body and the plug body from the top of the plug body to form an oil film to reduce the opening and closing torque of the valve and improve the sealing and service life. The working pressure can reach 64MPa; the maximum working temperature can reach 325 degrees, and the maximum diameter can reach 600mm.

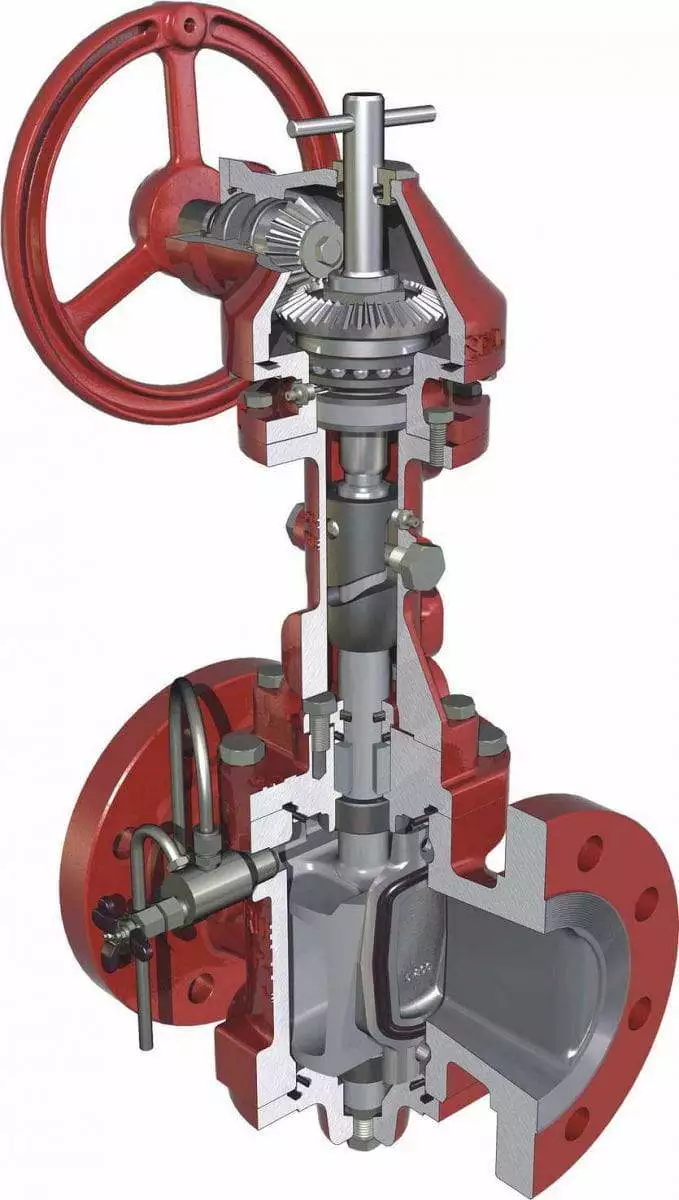

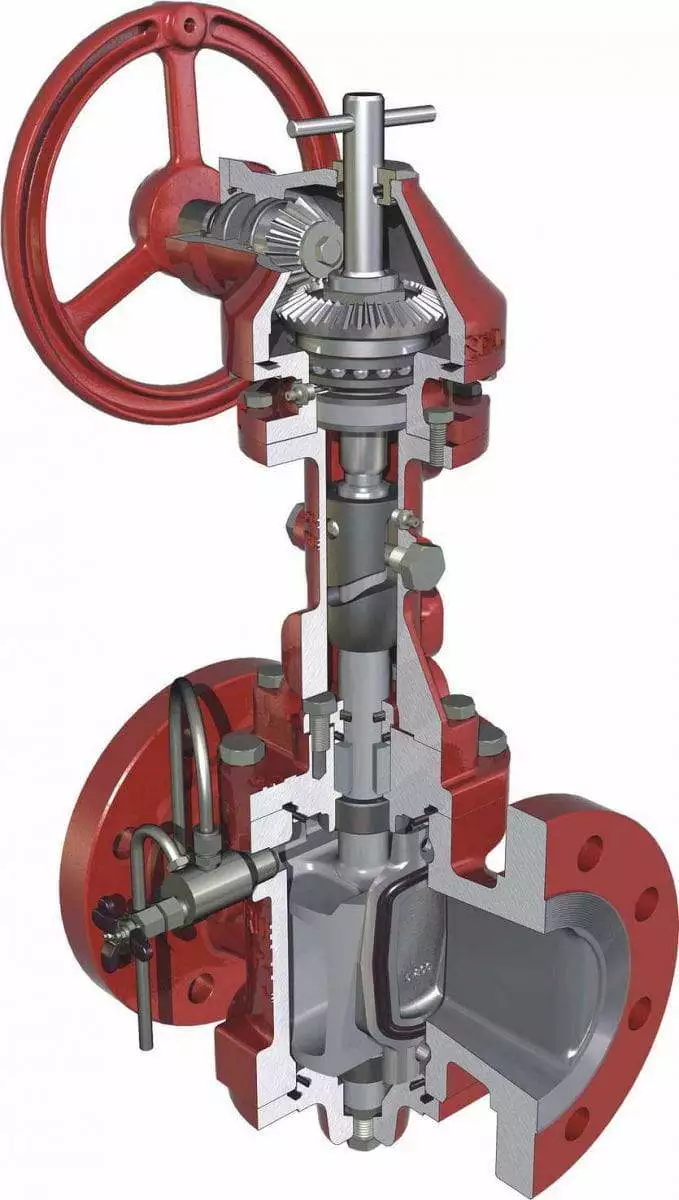

Lifting plug valves

Lifting plug valves are divided into soft seated lifting plug valves and metal seated lifting plug valves according to the material of the sealing surface. The basic principle is to make the plug rises when the valve is opened, and then turn it at an angle of 90 degrees until the valve is fully opened to reduce the friction with the sealing surface of the valve body; when the valve is closed, make the cock turn 90 degrees to the closed position and then descend to contact with the valve body achieve the purpose of sealing.

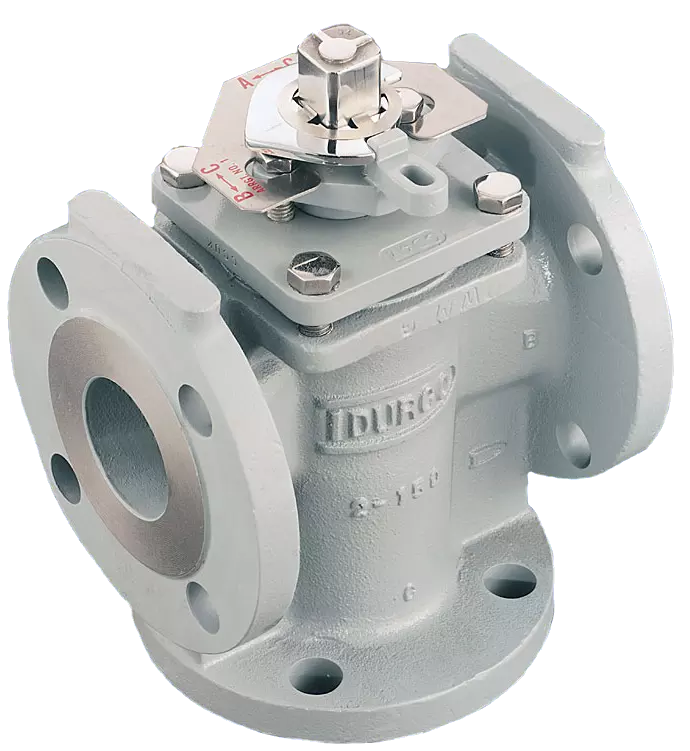

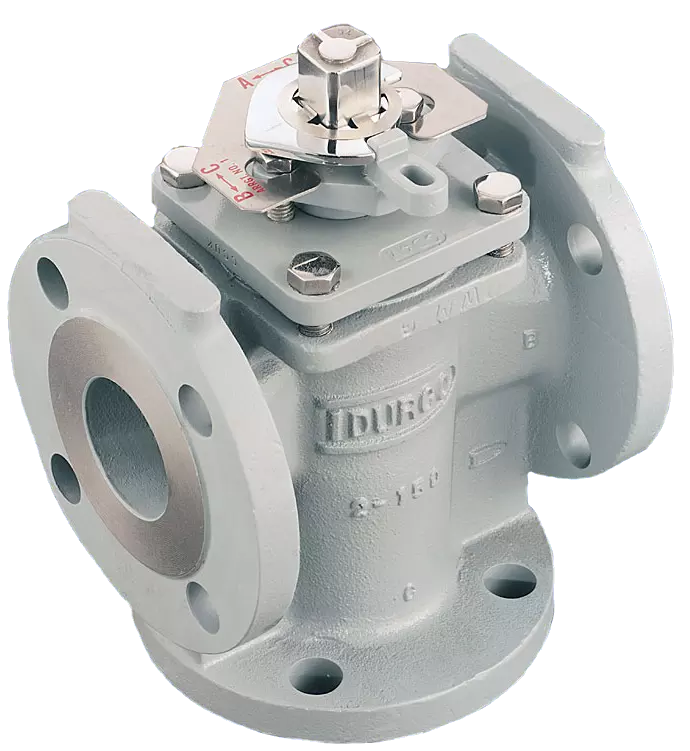

Three-way and four-way plug valves

The three-way and four-way plug valves are suitable for occasions where the flow direction of the medium is changed or the medium is distributed in the plant. According to the requirements of the working conditions, you can choose a soft-seated lining or a soft-seated, metal-seated lift plug valve.