Structural Features of Double Shut-off Plug Valves

Nov 20, 2023

Structural characteristics of double cut-off plug valves

The double shut-off plug valve is designed for dedicated occasions with strict requirements for sealing and cutting off (Figure 1). The plug valve has features of compact design, less space and light weight. Moreover, the advantage of this valve design is that the structural length is smaller than the conventional two shut-off valves and discharge valves. In most cases, the valve's structural length has the same size as an ordinary single plug valve or ball valve.

The double shut-off plug valve is designed based on the structure of the pressure-balanced inverted cone plug valve, so the operation and maintenance are the same as the pressure-balanced inverse cone plug valve. Because the only moving parts are the plug and the valve stem, the valve is simple to operate. When the cock rotates 90° clockwise, the valve completes the action from opening to closing, and vice versa. The taper of the plug is 1:6, and it is completely and well assembled with the valve body. It adopts a metal-to-metal seal, that is, it does not use a soft seal that is damaged by the flowing fluid.

The double shut-off plug valve is designed and manufactured based on the "pressure balanced" principle, which means that the plug is equipped with a pressure balance hole to ensure that the plug is always axially balanced to prevent the plug from getting stuck. In addition, in order to reduce the torque of the valve, the surface of the plug is sprayed with a PTFE protective layer using thermal spraying. The plug and the valve stem are two independent parts. They are connected into one with the help of a balance ring of a universal connecting piece. The valve stem cannot be arbitrarily taken out from the bottom when reassembling.

As a secondary seal, the valve provides an oil seal system that allows special sealing grease to be added to the valve's oil seal circuit when the valve is operated. In addition to sealing, it can also play a lubricating role to prevent corrosion and wear of internal parts, while also reducing the operating torque of the valve. The unique advantage of this valve is that it has three independent sealing methods. It is composed of a reinforced plate R-PTFE and a 100% pure graphite seal composed of a stainless steel backup ring. The use of graphite for sealing is very effective in ultra-high temperatures and situations that meet various demanding requirements for fire protection design of different standards.

The top of the valve stem is the primary sealing place. This is a PTFE sealing ring with an embedded special alloy spring. This sealing ring can be replaced from the outside. It is used to compress the valve stem bearing and split rings. In addition to the valve stem seal mentioned above, the manually operated valve has a waterproof sealing function to prevent water penetration and dirt from entering the valve stem.

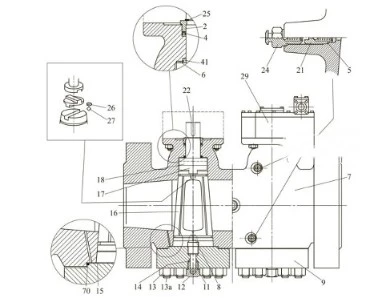

Figure 1 Double shut-off plug valves (parts)

2. Stem bearing 4. Sealing rings 5. Gaskets 6. Thrust gaskets 7. Valve bodies 8. Extension pieces 9. Bottom covers 11. Pressure adjustment screws 12. Bottom screws 13. Nuts 13a. Bolts 14. Fixing rings 15. Adjusting gaskets 16. Plug bodies 17. Balancing rings 18. Valve stems 21. One-way valves 22. Keys 24. Grease injection valves 25. Elastic clamp rings 26. Springs 27. Steel balls 29. Driving devices 41. Fireproof sealing gaskets 70. Graphite sealing rings

The bottom cover is fixed on the valve body with bolts and nuts. Two soft plates or diaphragms are placed in the groove between the valve body and the bottom cover. They mainly play the role of sealing by metal and also prevent leakages of the medium from adjusting the pressure, screw and the fixing ring and bottom screw.

This valve also has a new feature, which is the addition of a protective interface (between the two valve spools) to prevent internal cavitation, called a dedicated pressure relief port. This feature is a port from the valve body sealing surface opposite the diaphragm to the outside of each valve plug. When operating normally, the port is sealed by the pressure of the bottom cover, which is secured with bolts and nuts, against the direction of the diaphragm. When both valve spools are in the closed position and overpressure occurs, if the valve is easily affected by thermal stress, the pressure against the valve bottom cover will cause the bolt to deform (stretch), thereby opening the release valve; the pressure will be released into the pipe; the pipe pressure is released to the atmosphere within a very short time, and the deformation of the bottom screw exceeds the allowable limit value defined by the ASME/API specifications. When the pressure drops, the bolt returns to the bottom cover and closes the port.

In addition to the metal seal, there is a pure graphite sealing ring between the valve body and the bottom cover. Depending on the user's needs, the discharge port is provided accordingly, which allows a sealed entrance to the verified valve itself, through which any leakage past the first spool can be detected. Adjust the valve core through the pressure adjustment screw inside the valve body. When the bottom screw is tightened, fix the valve spool through the fixing ring. All adjustments to the valve spool are achieved through an adjustment washer consisting of two diaphragms.

As mentioned above, the valve provides an oil sealing system, which penetrates the allowable special sealing grease into the interior of the valve through the grease valve and the check valve. Sealing grease is sprayed into the groove through a high-pressure oil gun. This system ensures that all sealing surfaces have a thin layer of lubricant and in doing so achieves an effective secondary seal. In addition, the driving device connection plate of the double shut-off plug valve is designed according to ISO standards and can be matched with various actuators. The valve is fully bi-directional and has no installation direction restrictions and can be installed in any position.

The flow rate of double cut-off plug valves

This valve is designed according to the requirement of keeping the flow rate change to a minimum, in order to achieve the maximum flow area at the smallest flow rate change. The result of this design is that the CV value of this valve is the largest among products of similar specifications. Compared with two independent single plug valves of the same diameter, the flow rate of this valve is greater and the pressure loss is smaller.

The double shut-off plug valve is designed for dedicated occasions with strict requirements for sealing and cutting off (Figure 1). The plug valve has features of compact design, less space and light weight. Moreover, the advantage of this valve design is that the structural length is smaller than the conventional two shut-off valves and discharge valves. In most cases, the valve's structural length has the same size as an ordinary single plug valve or ball valve.

The double shut-off plug valve is designed based on the structure of the pressure-balanced inverted cone plug valve, so the operation and maintenance are the same as the pressure-balanced inverse cone plug valve. Because the only moving parts are the plug and the valve stem, the valve is simple to operate. When the cock rotates 90° clockwise, the valve completes the action from opening to closing, and vice versa. The taper of the plug is 1:6, and it is completely and well assembled with the valve body. It adopts a metal-to-metal seal, that is, it does not use a soft seal that is damaged by the flowing fluid.

The double shut-off plug valve is designed and manufactured based on the "pressure balanced" principle, which means that the plug is equipped with a pressure balance hole to ensure that the plug is always axially balanced to prevent the plug from getting stuck. In addition, in order to reduce the torque of the valve, the surface of the plug is sprayed with a PTFE protective layer using thermal spraying. The plug and the valve stem are two independent parts. They are connected into one with the help of a balance ring of a universal connecting piece. The valve stem cannot be arbitrarily taken out from the bottom when reassembling.

As a secondary seal, the valve provides an oil seal system that allows special sealing grease to be added to the valve's oil seal circuit when the valve is operated. In addition to sealing, it can also play a lubricating role to prevent corrosion and wear of internal parts, while also reducing the operating torque of the valve. The unique advantage of this valve is that it has three independent sealing methods. It is composed of a reinforced plate R-PTFE and a 100% pure graphite seal composed of a stainless steel backup ring. The use of graphite for sealing is very effective in ultra-high temperatures and situations that meet various demanding requirements for fire protection design of different standards.

The top of the valve stem is the primary sealing place. This is a PTFE sealing ring with an embedded special alloy spring. This sealing ring can be replaced from the outside. It is used to compress the valve stem bearing and split rings. In addition to the valve stem seal mentioned above, the manually operated valve has a waterproof sealing function to prevent water penetration and dirt from entering the valve stem.

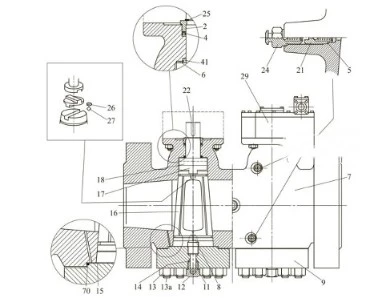

Figure 1 Double shut-off plug valves (parts)

2. Stem bearing 4. Sealing rings 5. Gaskets 6. Thrust gaskets 7. Valve bodies 8. Extension pieces 9. Bottom covers 11. Pressure adjustment screws 12. Bottom screws 13. Nuts 13a. Bolts 14. Fixing rings 15. Adjusting gaskets 16. Plug bodies 17. Balancing rings 18. Valve stems 21. One-way valves 22. Keys 24. Grease injection valves 25. Elastic clamp rings 26. Springs 27. Steel balls 29. Driving devices 41. Fireproof sealing gaskets 70. Graphite sealing rings

The bottom cover is fixed on the valve body with bolts and nuts. Two soft plates or diaphragms are placed in the groove between the valve body and the bottom cover. They mainly play the role of sealing by metal and also prevent leakages of the medium from adjusting the pressure, screw and the fixing ring and bottom screw.

This valve also has a new feature, which is the addition of a protective interface (between the two valve spools) to prevent internal cavitation, called a dedicated pressure relief port. This feature is a port from the valve body sealing surface opposite the diaphragm to the outside of each valve plug. When operating normally, the port is sealed by the pressure of the bottom cover, which is secured with bolts and nuts, against the direction of the diaphragm. When both valve spools are in the closed position and overpressure occurs, if the valve is easily affected by thermal stress, the pressure against the valve bottom cover will cause the bolt to deform (stretch), thereby opening the release valve; the pressure will be released into the pipe; the pipe pressure is released to the atmosphere within a very short time, and the deformation of the bottom screw exceeds the allowable limit value defined by the ASME/API specifications. When the pressure drops, the bolt returns to the bottom cover and closes the port.

In addition to the metal seal, there is a pure graphite sealing ring between the valve body and the bottom cover. Depending on the user's needs, the discharge port is provided accordingly, which allows a sealed entrance to the verified valve itself, through which any leakage past the first spool can be detected. Adjust the valve core through the pressure adjustment screw inside the valve body. When the bottom screw is tightened, fix the valve spool through the fixing ring. All adjustments to the valve spool are achieved through an adjustment washer consisting of two diaphragms.

As mentioned above, the valve provides an oil sealing system, which penetrates the allowable special sealing grease into the interior of the valve through the grease valve and the check valve. Sealing grease is sprayed into the groove through a high-pressure oil gun. This system ensures that all sealing surfaces have a thin layer of lubricant and in doing so achieves an effective secondary seal. In addition, the driving device connection plate of the double shut-off plug valve is designed according to ISO standards and can be matched with various actuators. The valve is fully bi-directional and has no installation direction restrictions and can be installed in any position.

The flow rate of double cut-off plug valves

This valve is designed according to the requirement of keeping the flow rate change to a minimum, in order to achieve the maximum flow area at the smallest flow rate change. The result of this design is that the CV value of this valve is the largest among products of similar specifications. Compared with two independent single plug valves of the same diameter, the flow rate of this valve is greater and the pressure loss is smaller.

Previous: Analysis of the Causes of Cracking of Main Steam Pipe Globe Valves

Next: Anti-corrosion of Valve Surfaces in the Petrochemical Industry