Principles and Structural Characteristics of Elastic Seated Gate Valves

Apr 12, 2023

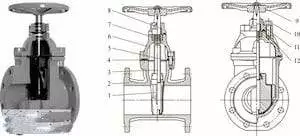

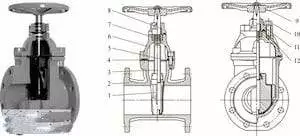

The core components of elastic seated gate valves mainly include valve bodies, bonnets, valve stems and valve plates, as shown in Figure 1. The valve plate is made of nodular cast iron covered with non-toxic rubber (direct vulcanized nitrile rubber or EPDM rubber). The sealing of the whole valve mainly depends on the contact between the rubber gate and the casting. The micro elastic deformation of the rubber due to the force can achieve a good sealing effect. The sealing is reliable and can achieve zero leakage, and the friction factor is small; the wear is small. The valve has small torque, easy operation, long service life, no pollution, corrosion resistance and beautiful appearance when it is opened or closed.

Figure 1 Rising stem elastic seat seal gate valves

1. Valve plates 2. Valve bodies 3. Valve stems 4. Sealing gaskets 5. Hexagon head screws 6. Valve bonnets 7. Thrust bearing 8 &12. O rings 9. Handwheels 10. Screws 11. Packing gland

The resilient seated gate valve has the following advantages:

1. Flat bottom valve seats

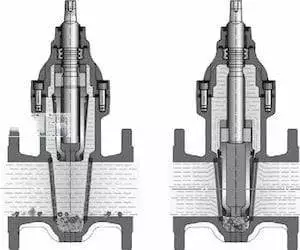

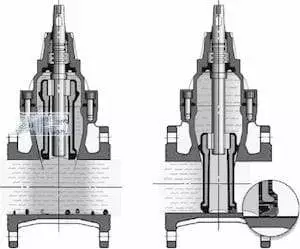

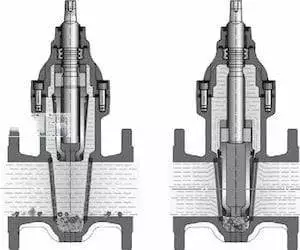

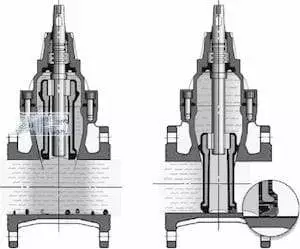

Traditional metal gate valves can’t be closed well and leak because foreign objects such as stones, wood blocks, cement, iron filings and sundries usually deposit in the groove of the bottom of the valve after being cleaned by water, as shown in Figure 2. The elastic seat seal gate valve adopts a flat bottom design with no groove at the bottom of the inner cavity and the same bottom as the water pipe, which is not easy to cause debris to accumulate, and the seal is consistent, as shown in Figure 3.

Figure 2 When the medium with particles passes through the traditional metal valve

Figure 3 When the medium with particles passes through the elastic seated gate valve

2. The whole wedge covered with rubber

The valve plate is covered with high-quality rubber. The first-class rubber vulcanization technology enables the vulcanized valve plate to ensure accurate geometric dimensions, and the rubber is firmly attached to the ductile iron, which is not easy to fall off and has good elastic memory.

3. All parts meeting the requirements for environmental protection

The valve body, bonnet, bracket, handwheel, transmission cap and other parts of the elastic seated gate valve are all made from ductile iron. After special treatment, the inner and outer surfaces are sprayed with epoxy resin powder coating by a high-voltage electrostatic spraying process. Stainless steel or copper alloy is used to effectively prevent the formation of corrosion, and it is non-polluting, non-toxic and has a beautiful surface.

4. Small flow resistance and small loss

Due to the spraying process of the elastic seat gate valve, the surface of the epoxy resin coating is very smooth, which greatly reduces the surface roughness of the channel through which the medium flows, so the flow resistance is small and the loss is small; at the same time, the bottom of the valve body is designed as a straight-through type, which reduces flow resistance and head loss.

5. Special shaft seal

Since the valve stem is sealed with three O-rings and one dust-proof ring, the frictional resistance during closing or opening can be reduced, and leakage can be greatly reduced.

6. Protective devices

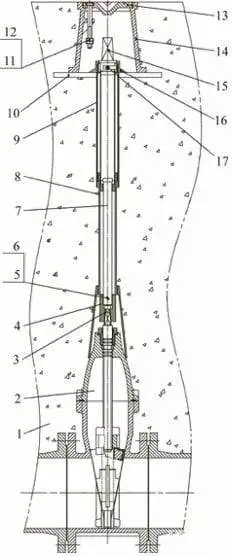

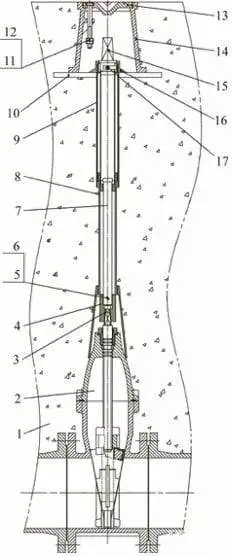

The lawsuits and claims caused by the theft of the manhole cover and the fall of pedestrians are avoided. The elastic seat gate valve that can be directly buried in the ground is equipped with a set of protective devices. There is a valve box on the top of the device. Opening the cover plate on the valve box can open and close the valve with an extended socket wrench. Figure 4 shows the buried underground non-rising stem elastic seated gate valves.

Figure 4 Underground non-rising stem elastic seated gate valves

Rammed earth layers 2. Valves 3. Hexagon screws 4. Connecting square heads 5. Cotter pins 6. Location pins 7. Transmission rods 8 & 9. Protective covers 11. Nuts 12. Bolts 13. Cover plates 14. Valve boxes 15. Drive caps 16. Positioning covers 17. Plastic snap rings

Figure 1 Rising stem elastic seat seal gate valves

1. Valve plates 2. Valve bodies 3. Valve stems 4. Sealing gaskets 5. Hexagon head screws 6. Valve bonnets 7. Thrust bearing 8 &12. O rings 9. Handwheels 10. Screws 11. Packing gland

The resilient seated gate valve has the following advantages:

1. Flat bottom valve seats

Traditional metal gate valves can’t be closed well and leak because foreign objects such as stones, wood blocks, cement, iron filings and sundries usually deposit in the groove of the bottom of the valve after being cleaned by water, as shown in Figure 2. The elastic seat seal gate valve adopts a flat bottom design with no groove at the bottom of the inner cavity and the same bottom as the water pipe, which is not easy to cause debris to accumulate, and the seal is consistent, as shown in Figure 3.

Figure 2 When the medium with particles passes through the traditional metal valve

Figure 3 When the medium with particles passes through the elastic seated gate valve

2. The whole wedge covered with rubber

The valve plate is covered with high-quality rubber. The first-class rubber vulcanization technology enables the vulcanized valve plate to ensure accurate geometric dimensions, and the rubber is firmly attached to the ductile iron, which is not easy to fall off and has good elastic memory.

3. All parts meeting the requirements for environmental protection

The valve body, bonnet, bracket, handwheel, transmission cap and other parts of the elastic seated gate valve are all made from ductile iron. After special treatment, the inner and outer surfaces are sprayed with epoxy resin powder coating by a high-voltage electrostatic spraying process. Stainless steel or copper alloy is used to effectively prevent the formation of corrosion, and it is non-polluting, non-toxic and has a beautiful surface.

4. Small flow resistance and small loss

Due to the spraying process of the elastic seat gate valve, the surface of the epoxy resin coating is very smooth, which greatly reduces the surface roughness of the channel through which the medium flows, so the flow resistance is small and the loss is small; at the same time, the bottom of the valve body is designed as a straight-through type, which reduces flow resistance and head loss.

5. Special shaft seal

Since the valve stem is sealed with three O-rings and one dust-proof ring, the frictional resistance during closing or opening can be reduced, and leakage can be greatly reduced.

6. Protective devices

The lawsuits and claims caused by the theft of the manhole cover and the fall of pedestrians are avoided. The elastic seat gate valve that can be directly buried in the ground is equipped with a set of protective devices. There is a valve box on the top of the device. Opening the cover plate on the valve box can open and close the valve with an extended socket wrench. Figure 4 shows the buried underground non-rising stem elastic seated gate valves.

Figure 4 Underground non-rising stem elastic seated gate valves

Rammed earth layers 2. Valves 3. Hexagon screws 4. Connecting square heads 5. Cotter pins 6. Location pins 7. Transmission rods 8 & 9. Protective covers 11. Nuts 12. Bolts 13. Cover plates 14. Valve boxes 15. Drive caps 16. Positioning covers 17. Plastic snap rings

Previous: The Installation and Operation of the Y Globe Valves

Next: Valves Used for Chemical Systems