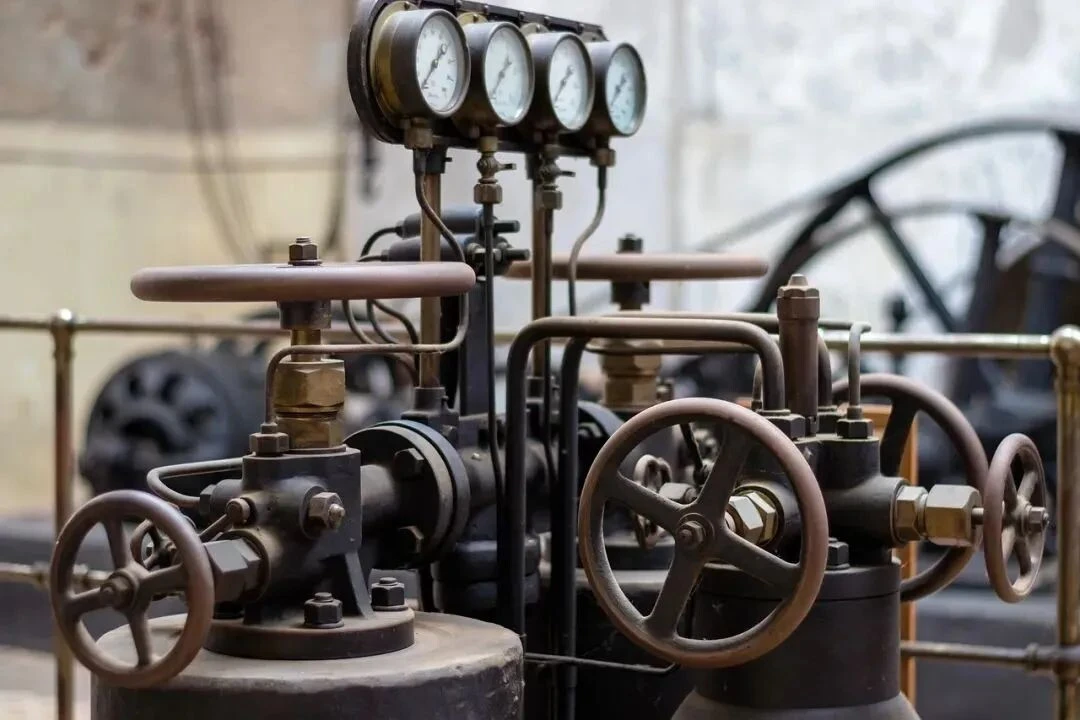

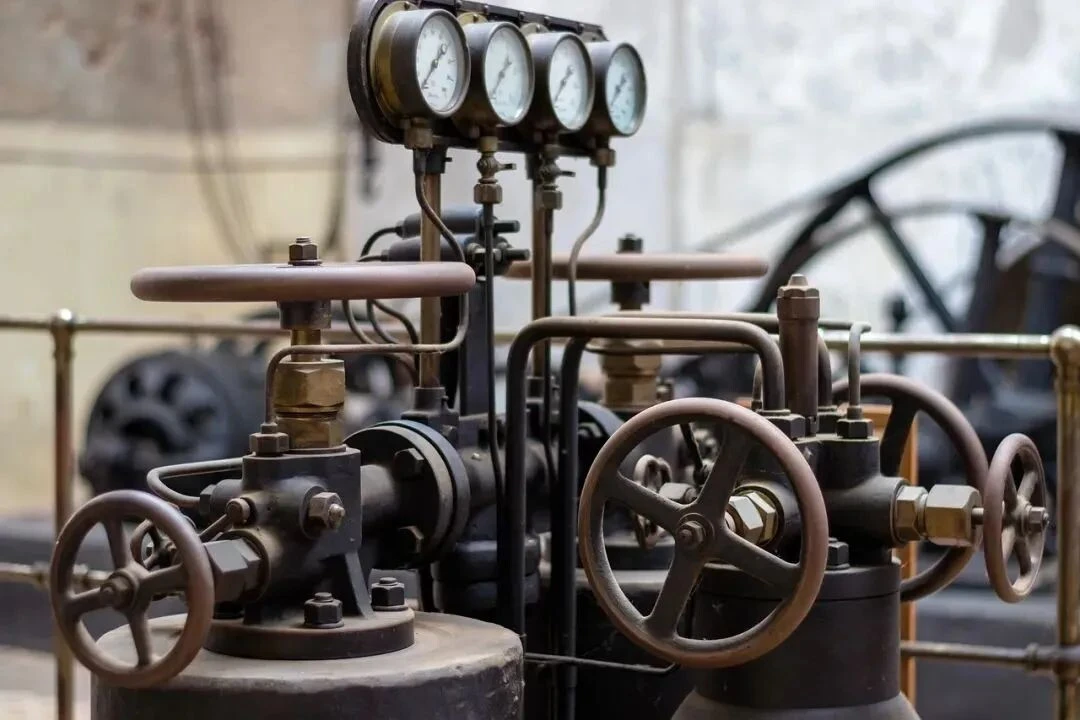

How to Prevent Corrosion of Valves?

Apr 08, 2024

Valves are crucial control equipment in industries such as chemical, petroleum, food, and others. However, during the transportation of corrosive mediums, valves are susceptible to corrosion damage, which affects their functionality and lifespan. Therefore, implementing effective corrosion prevention methods is essential for safeguarding valves and ensuring industrial production safety. This article will introduce several common methods for preventing valve corrosion.

Principles of Valve Corrosion Prevention mainly include two aspects: chemical corrosion prevention and electrochemical corrosion prevention. Chemical corrosion prevention primarily involves forming a corrosion-resistant coating on the surface of valve materials to prevent direct contact between corrosive mediums and valve materials. Electrochemical corrosion prevention involves making the valve the cathode of a corrosion cell through sacrificial anodes or applied currents to prevent corrosion.

Methods:

1. Surface Treatment: Clean, polish and degrease the valve surface to remove dirt and impurities, improving surface smoothness, and roughness, and facilitating the adhesion of subsequent coatings.

2. Coating Protection: Apply a corrosion-resistant coating such as epoxy resin, or polyurethane on the valve surface to form a protective film that blocks the penetration of corrosive mediums.

3. Plating: Electroplate a corrosion-resistant metal such as chromium, or nickel on the valve surface to enhance its corrosion resistance.

4. Cathodic Protection: By applying an external current, make the valve the cathode of a corrosion cell to prevent corrosion. This method is mainly suitable for valves used underground or underwater.

When selecting valve corrosion prevention methods, the following aspects need to be considered:

1. Nature of the Corrosive Medium: Different corrosive mediums require different corrosion prevention methods.

2. Operating Environment: The operating environment has a significant impact on the selection of corrosion prevention methods, such as temperature, humidity, and pressure.

3. Valve Type: Different types of valves require different corrosion prevention methods, such as ball valves, gate valves, and globe valves.

4. Maintenance: Different corrosion prevention methods require different maintenance measures.

Case Study:

A chemical plant's acid delivery pipeline used stainless steel valves. However, due to the highly corrosive nature of the medium, the sealing surfaces of the valves were frequently corroded. To address this issue, the following measures were taken:

1. Clean, polish, and degrease the valve surface to improve surface smoothness and roughness.

2. Use special acid-resistant stainless steel materials for the valve body and internal components to enhance the valve's corrosion resistance.

3. Apply a layer of corrosion-resistant coating, such as epoxy resin, on the valve sealing surfaces to form a protective film that blocks the penetration of corrosive mediums.

4. Strengthen valve maintenance: regularly inspect and replace sealing materials to maintain the valve in good working condition.

By implementing these measures, the corrosion problem of stainless steel valves in the acid delivery pipeline was effectively solved, ensuring production safety and efficiency.

Summary:

Valve corrosion prevention is an important measure to ensure industrial production safety and stability. When selecting valve corrosion prevention methods, practical considerations need to be taken into account to choose the appropriate methods. At the same time, strengthening valve maintenance, and regularly inspecting and replacing sealing materials to keep the valve in good working condition, is also an important measure to prevent valve corrosion damage.

Principles of Valve Corrosion Prevention mainly include two aspects: chemical corrosion prevention and electrochemical corrosion prevention. Chemical corrosion prevention primarily involves forming a corrosion-resistant coating on the surface of valve materials to prevent direct contact between corrosive mediums and valve materials. Electrochemical corrosion prevention involves making the valve the cathode of a corrosion cell through sacrificial anodes or applied currents to prevent corrosion.

Methods:

1. Surface Treatment: Clean, polish and degrease the valve surface to remove dirt and impurities, improving surface smoothness, and roughness, and facilitating the adhesion of subsequent coatings.

2. Coating Protection: Apply a corrosion-resistant coating such as epoxy resin, or polyurethane on the valve surface to form a protective film that blocks the penetration of corrosive mediums.

3. Plating: Electroplate a corrosion-resistant metal such as chromium, or nickel on the valve surface to enhance its corrosion resistance.

4. Cathodic Protection: By applying an external current, make the valve the cathode of a corrosion cell to prevent corrosion. This method is mainly suitable for valves used underground or underwater.

When selecting valve corrosion prevention methods, the following aspects need to be considered:

1. Nature of the Corrosive Medium: Different corrosive mediums require different corrosion prevention methods.

2. Operating Environment: The operating environment has a significant impact on the selection of corrosion prevention methods, such as temperature, humidity, and pressure.

3. Valve Type: Different types of valves require different corrosion prevention methods, such as ball valves, gate valves, and globe valves.

4. Maintenance: Different corrosion prevention methods require different maintenance measures.

Case Study:

A chemical plant's acid delivery pipeline used stainless steel valves. However, due to the highly corrosive nature of the medium, the sealing surfaces of the valves were frequently corroded. To address this issue, the following measures were taken:

1. Clean, polish, and degrease the valve surface to improve surface smoothness and roughness.

2. Use special acid-resistant stainless steel materials for the valve body and internal components to enhance the valve's corrosion resistance.

3. Apply a layer of corrosion-resistant coating, such as epoxy resin, on the valve sealing surfaces to form a protective film that blocks the penetration of corrosive mediums.

4. Strengthen valve maintenance: regularly inspect and replace sealing materials to maintain the valve in good working condition.

By implementing these measures, the corrosion problem of stainless steel valves in the acid delivery pipeline was effectively solved, ensuring production safety and efficiency.

Summary:

Valve corrosion prevention is an important measure to ensure industrial production safety and stability. When selecting valve corrosion prevention methods, practical considerations need to be taken into account to choose the appropriate methods. At the same time, strengthening valve maintenance, and regularly inspecting and replacing sealing materials to keep the valve in good working condition, is also an important measure to prevent valve corrosion damage.

Previous: API Strengthens Oil Well Safety through Updated Valve Standards

Next: Air Control Valves