Different Types of Wedge Gate Valves

Dec 18, 2023

The common types of wedge gate valves include rising stem single wedge gate valves, non-rising stem single wedge gate valves, rising stem double wedge gate valves, non-rising stem double wedge gate valves, and purge gate valves.

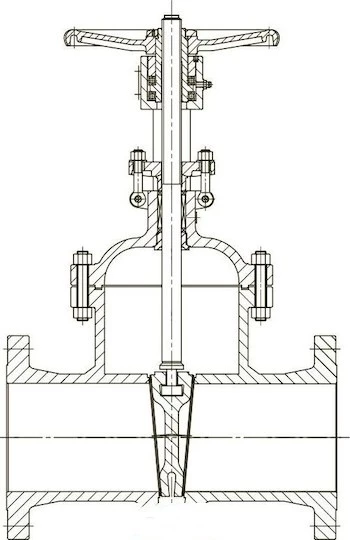

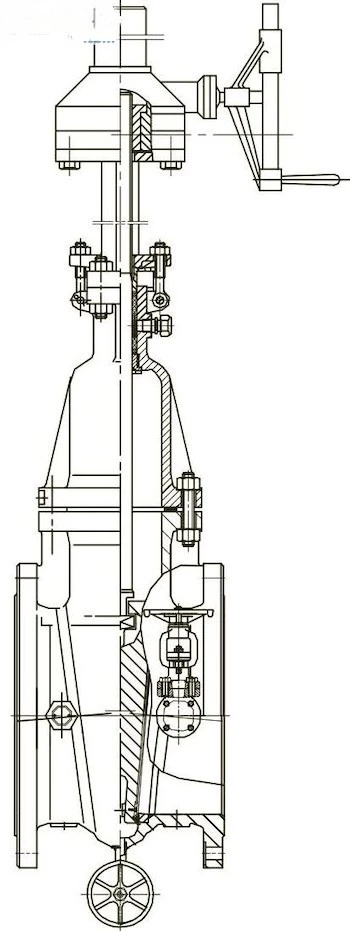

1. Rising stem single wedge gate valves

The wedge of the rising stem single wedge gate valve is a single wedge (Figure 1). One end of the valve stem has a trapezoidal transmission thread, and the valve stem and the wedge are connected through a T-shaped slot. A valve stem nut is fixed on the upper part of the valve bonnet, and a handwheel is installed outside the valve stem nut. When the handwheel is rotated counterclockwise, the valve stem drives the valve plate up and the valve can be opened; when the handwheel is rotated clockwise, the valve stem descends; eventually wedges the valve plate well, and the valve closes.

Figure 1 Rising stem single wedge gate valves

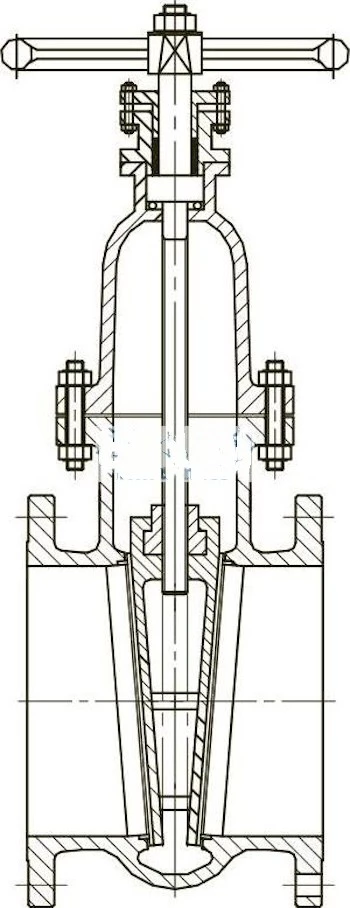

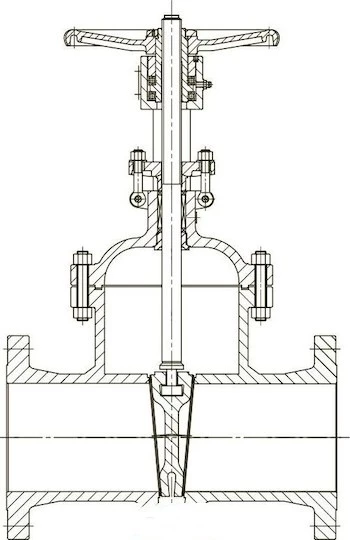

2. Non rising stem single wedge gate valves

Figure 2 shows a non rising stem single wedge gate valve. There is a through hole in the middle of the wedge plate, and the guide grooves on both sides of the non-sealing surface cooperate with the guide ribs on the valve body to form a guide device. The groove on the upper part of the wedge is equipped with a valve stem nut with a trapezoidal thread, which forms a transmission pair with the trapezoidal thread at the lower end of the valve stem. It is operated by the handwheel installed on the top of the valve stem. When the handwheel is rotated clockwise, the valve stem rotates and the wedge is lowered and wedged well; the valve is closed; when the handwheel is rotated counterclockwise, the wedge is raised and the valve is opened.

Figure 2 Non rising stem single wedge gate valves

The valve stem of the non rising stem wedge gate valve only performs rotational motion when the valve is opened or closed, but does not rise or fall. Therefore, the valve stem is not tall, which is also conducive to the sealing of the valve stem packing. In order to determine the opening and closing position of the wedge, a special indicator can be used. The single wedge gate valve has relatively simple structure and has no parts that are easy to wear inside. However, the processing and maintenance of the wedge sealing surface of this kind of valve are relatively complicated. It is generally used in media with a temperature below 200 to 250°C. When the temperature is high, the wedge plate is in danger of getting stuck because the valve body and wedge are affected by uneven thermal expansion. If the sealing surface of the wedge plate is highly precision processed and carefully adjusted, it can also be suitable for higher operating temperatures. Wedge gate valves can be installed at any position, that is, the valve stem can be positioned vertically up or down, or at an angle to the pipe.

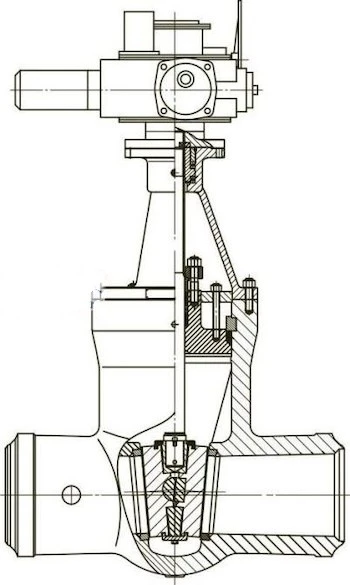

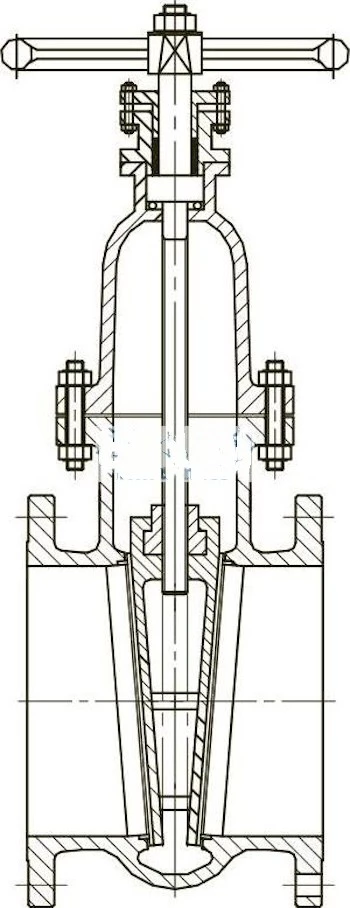

3. Rising stem double wedge gate valves

Figure 3 shows a rising stem double wedge gate valve. There are two disc plates installed in the valve body, which are combined by the hemispherical core in the middle. The angle between the two sealing surfaces can be determined according to the angle between the two valve seats, eliminating unfavorable factors caused by machining errors and deformation of valve bodies. between the two sealing surfaces and achieves better sealing. Double wedge gate valves are only allowed to be installed on horizontal pipelines, and the valve stem must be installed vertically upward. However, the stems of double wedge gate valves in many pipelines are installed horizontally, causing the hemispherical core to fall toward the valve body instead of the bottom of the valve. This not only cause the hemispherical core not to function properly, but also cause the valve to not close well and make it difficult to open and close.

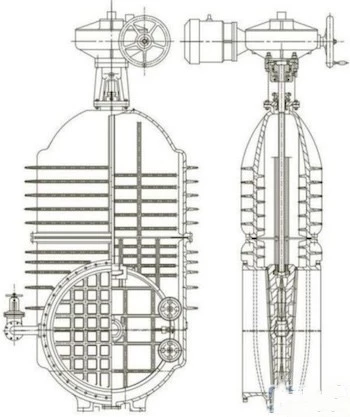

Figure 3 Rising stem double wedge gate valves

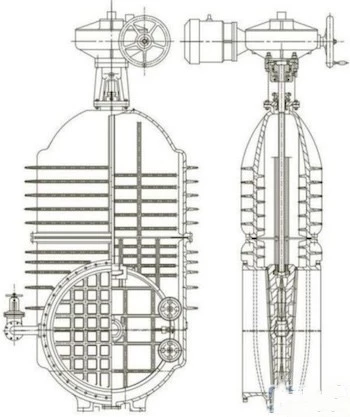

4. Non rising stem double wedge gate valves

Figure 4 shows a non rising stem double wedge gate valve. Compared with the single wedge valve, the advantage of the double wedge gate valve is that the wedge sealing surface of the plate and the valve seat has better sealing and is more convenient to process. In addition, when the valve is affected by high temperature and high pressure and the valve body deforms, the two sealing surfaces of the double wedge can move together with the valve body under the action of the valve stem’s wedge force, thus ensuring good sealing and lowing the probability of the wedge from getting stuck.

Figure 4 Non rising stem double wedge gate valves

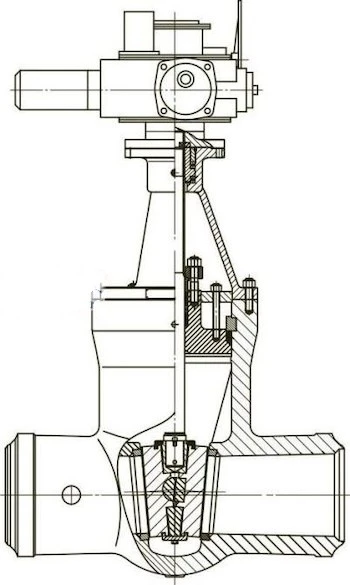

5. Purge gate valves

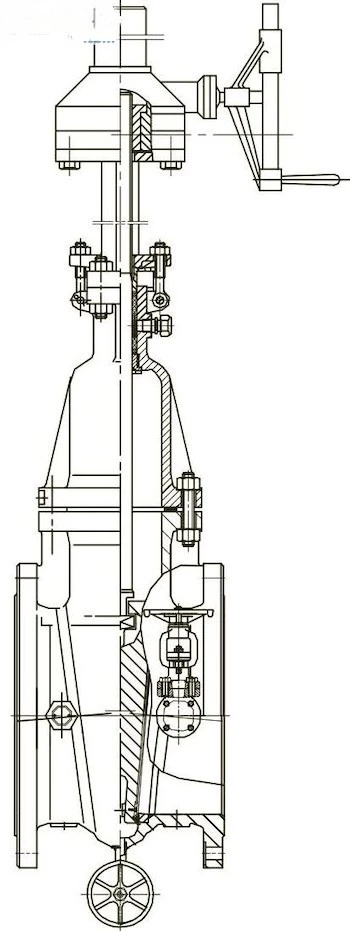

Figure 5 shows a rising stem single wedge high-temperature purge gate valve. This valve is based on the ordinary single wedge gate valve, with a purging device added to the valve body and valve bonnet. High-pressure water or steam is injected through the purging device to clean pipelines and valves that are prone to coking and contain granular media, achieving online removal of impurities in pipelines and valves, which has the advantages of convenience, time saving and effectively increases the service life of the system. It is suitable for use as an opening and closing device on pipelines containing water, steam, flue gas, oil, mist, powder, granular and other media. It is especially suitable for oil transportation and catalytic cracking units in the petrochemical industry, which can be opened, closed and clean the pipeline.

Figure 5 Rising stem single wedge high-temperature purge gate valves

1. Rising stem single wedge gate valves

The wedge of the rising stem single wedge gate valve is a single wedge (Figure 1). One end of the valve stem has a trapezoidal transmission thread, and the valve stem and the wedge are connected through a T-shaped slot. A valve stem nut is fixed on the upper part of the valve bonnet, and a handwheel is installed outside the valve stem nut. When the handwheel is rotated counterclockwise, the valve stem drives the valve plate up and the valve can be opened; when the handwheel is rotated clockwise, the valve stem descends; eventually wedges the valve plate well, and the valve closes.

Figure 1 Rising stem single wedge gate valves

2. Non rising stem single wedge gate valves

Figure 2 shows a non rising stem single wedge gate valve. There is a through hole in the middle of the wedge plate, and the guide grooves on both sides of the non-sealing surface cooperate with the guide ribs on the valve body to form a guide device. The groove on the upper part of the wedge is equipped with a valve stem nut with a trapezoidal thread, which forms a transmission pair with the trapezoidal thread at the lower end of the valve stem. It is operated by the handwheel installed on the top of the valve stem. When the handwheel is rotated clockwise, the valve stem rotates and the wedge is lowered and wedged well; the valve is closed; when the handwheel is rotated counterclockwise, the wedge is raised and the valve is opened.

Figure 2 Non rising stem single wedge gate valves

The valve stem of the non rising stem wedge gate valve only performs rotational motion when the valve is opened or closed, but does not rise or fall. Therefore, the valve stem is not tall, which is also conducive to the sealing of the valve stem packing. In order to determine the opening and closing position of the wedge, a special indicator can be used. The single wedge gate valve has relatively simple structure and has no parts that are easy to wear inside. However, the processing and maintenance of the wedge sealing surface of this kind of valve are relatively complicated. It is generally used in media with a temperature below 200 to 250°C. When the temperature is high, the wedge plate is in danger of getting stuck because the valve body and wedge are affected by uneven thermal expansion. If the sealing surface of the wedge plate is highly precision processed and carefully adjusted, it can also be suitable for higher operating temperatures. Wedge gate valves can be installed at any position, that is, the valve stem can be positioned vertically up or down, or at an angle to the pipe.

3. Rising stem double wedge gate valves

Figure 3 shows a rising stem double wedge gate valve. There are two disc plates installed in the valve body, which are combined by the hemispherical core in the middle. The angle between the two sealing surfaces can be determined according to the angle between the two valve seats, eliminating unfavorable factors caused by machining errors and deformation of valve bodies. between the two sealing surfaces and achieves better sealing. Double wedge gate valves are only allowed to be installed on horizontal pipelines, and the valve stem must be installed vertically upward. However, the stems of double wedge gate valves in many pipelines are installed horizontally, causing the hemispherical core to fall toward the valve body instead of the bottom of the valve. This not only cause the hemispherical core not to function properly, but also cause the valve to not close well and make it difficult to open and close.

Figure 3 Rising stem double wedge gate valves

4. Non rising stem double wedge gate valves

Figure 4 shows a non rising stem double wedge gate valve. Compared with the single wedge valve, the advantage of the double wedge gate valve is that the wedge sealing surface of the plate and the valve seat has better sealing and is more convenient to process. In addition, when the valve is affected by high temperature and high pressure and the valve body deforms, the two sealing surfaces of the double wedge can move together with the valve body under the action of the valve stem’s wedge force, thus ensuring good sealing and lowing the probability of the wedge from getting stuck.

Figure 4 Non rising stem double wedge gate valves

5. Purge gate valves

Figure 5 shows a rising stem single wedge high-temperature purge gate valve. This valve is based on the ordinary single wedge gate valve, with a purging device added to the valve body and valve bonnet. High-pressure water or steam is injected through the purging device to clean pipelines and valves that are prone to coking and contain granular media, achieving online removal of impurities in pipelines and valves, which has the advantages of convenience, time saving and effectively increases the service life of the system. It is suitable for use as an opening and closing device on pipelines containing water, steam, flue gas, oil, mist, powder, granular and other media. It is especially suitable for oil transportation and catalytic cracking units in the petrochemical industry, which can be opened, closed and clean the pipeline.

Figure 5 Rising stem single wedge high-temperature purge gate valves

Previous: Problems and Measures in High Sulfur Natural Gas Field Valves (Part Two)

Next: Stainless Steel Valves