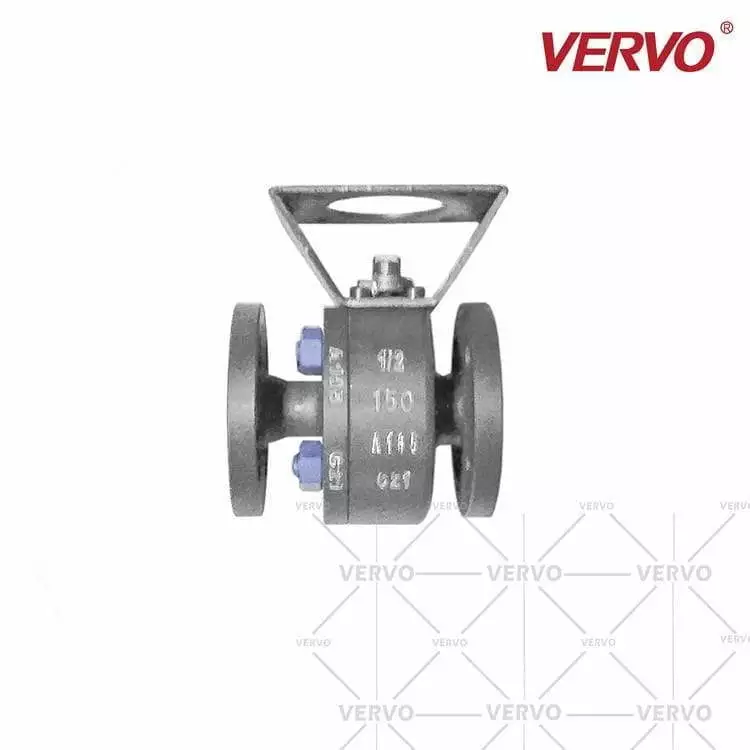

High Platform Floating Ball Valve, DN15-DN1000, 150-2500 LB

High Platform Floating Ball Valve is a type of industrial valve designed for high-pressure applications. This valve features a floating ball that seals against the valve seat to prevent leakage. It is commonly used in oil and gas, chemical processing, and other industrial processes. With its durable construction and reliable performance, High Platform Floating Ball Valve is the ideal choice for applications where safety and efficiency are paramount. Contact us today to learn more about this versatile valve.

Categories

- Ball Valves

Tags

- Floating Ball Valves , DN15 Ball Valve , DN1000 Ball Valve

Detail Information

High Platform Floating Ball Valve

Nominal pressure: PN1.6-42MPa, ANSI 150-2500 LB

Nominal diameter (mm): DN15-DN1000

Connection Type: Flange, Thread, Butt welding, Socket welding

Body material: ASTM A352 LCB, ASTM A216 WCB, ASTM A351 CF8, ASTM A351 CF8M, ASTM A351 CF3, ASTM A351 CF3M

Valve seat form: Soft seat, metal seat (hardened sealing surface)

Proper temperature:

Soft seat: -20 - + 200℃

Metal seat: -196 - + 400℃

Leakage level: ANSI VI

Design standards: GB/T 12237, ASME B16.34

Structure length: GB/T 12221, ASME B16.10

Testing standards: GB/T 13927, API 598

Operation method: Manual, pneumatic, electric, etc.

Optional: Anti-static design, fire protection design, oil-free treatment, Copper

Prohibition, Spherical special treatment, Customers request painting

Main parts materials

Nominal pressure: PN1.6-42MPa, ANSI 150-2500 LB

Nominal diameter (mm): DN15-DN1000

Connection Type: Flange, Thread, Butt welding, Socket welding

Body material: ASTM A352 LCB, ASTM A216 WCB, ASTM A351 CF8, ASTM A351 CF8M, ASTM A351 CF3, ASTM A351 CF3M

Valve seat form: Soft seat, metal seat (hardened sealing surface)

Proper temperature:

Soft seat: -20 - + 200℃

Metal seat: -196 - + 400℃

Leakage level: ANSI VI

Design standards: GB/T 12237, ASME B16.34

Structure length: GB/T 12221, ASME B16.10

Testing standards: GB/T 13927, API 598

Operation method: Manual, pneumatic, electric, etc.

Optional: Anti-static design, fire protection design, oil-free treatment, Copper

Prohibition, Spherical special treatment, Customers request painting

Main parts materials

| PART NAME | MATERIAL |

| Body | ASTM A216 WCB, ASTM A351 CF8, ASTM A351 CF8M, ASTM A351 CF3M |

| Bonnet | ASTM A216 WCB, ASTM A351 CF8, ASTM A351 CF8M, ASTM A351 CF3M |

| Ball body | SS 304, SS 316, SS316L, SS 316L + STL |

| Seat | PTFE, PPL, Metal seal, etc. |

| Stem | SS 304, SS 316, SS 316L, 17-4PH, S20910 |

| Middle head gasket | PTFE, PPL, Metal gasket |

| Inverted seal | PTFE, PPL, Stainless steel spiral graphite |

| O-ring | VITON |

| Filler | PTFE, PPL, Flexible graphite |

| Filling clamping ring | SS 304 |

| Butterfly spring | SS 304 |

| NUT | 2H, SS 304 |

| Gland of valve | ASTM A351 CF8 |

| Screw | B7, SS 304 |

| NUT | 2H, SS304 |

| Screw | B7, SS 304 |

Next: Pneumatic Flange Ball Valve, 1/2 - 8 Inch, DN15-DN200, PN16

Previous: Four Way Three Position Ball Valve, 1/2-8 Inch, DN15-DN200