Gate Valves

What is a gate valve?

Applications of gate valves

Low Temperature Gate Valve, CL150, 1 IN, A105N, API 602

ASTM A182 F316L Gate Valve, API 602, Bolted Bonnet, 1/2IN CL800

API 602 ASTM A182 F11 Gate Valves, 12 Inch, Class 800, NPT-F

High Temperature Gate Valve, API 602, A105N, 1/2 IN, 800 LB

API 602 Carbon Steel Gate Valve, BB, 800 LB, 1/2 IN, A105N

API 602 Socket Weld Gate Valves, ASTM A105N, 3/4 IN, 800 LB

Low Temperature Gate Valve, ASTM A350 LF2, NPS 1/2 IN, CL300

ASTM A182 F11 Gate Valves, API 602, 1/2 Inch, Class 300 LB

Carbon Steel ASTM A105N Gate Valve, API 602, 1 Inch, 150 LB

High Temperature Gate Valves, A182 F11, 1 IN, Class 300 LB

API 602 Bolted Bonnet Gate Valve, ASTM A105N, CL600, 3/4 IN

API 602 Forged Steel Gate Valve, 3/4 IN, 800 LB, A105N, SW

Parts of Gate Valves

Bodies

Seats

Wedges

Stems

Packing

Bonnets

Stands

Actuators

Advantages of gate valves

Small fluid resistance

Small opening and closing resistance

Non-restricted flow directions of the medium

Short structure length

Good sealing performance

Long service life

Less or no water hammer

Gate valves classified by structure

Wedge gate valves

Knife gate valves

A special valve called a knife gate valve is used to cut off plastic solids and slurries with high viscosity. Knife gate valves are generally not wedge-shaped, having tapered knife-like edges on their lower surface. The appearance of the knife gate valve solves the problems of heavy weights, large flow resistance, large area and difficult installation for ordinary gate valves, which can be used to replace the general shut-off valve and can work under the working pressure of 1.0MPa to 2.5MPa and operating temperature -29 to 550℃. The plate of the knife gate valve has a shearing function, which can scrape the adhesion on the sealing surface and automatically remove the sundries. The stainless steel plate can prevent leakages of sealing caused by corrosion. A knife gate valve is suitable for oil, water and steam pipelines for mining power plants, urban sewage treatment, food, paper, medicine, petroleum, chemical and other fields, connecting or cutting off cement slurry and gold ore powder, ore, slag, coal slime, pulp, wood pulp, tailings, fiber, dust, chemical treatment sewage, sedimentation tank, asphalt, fruit, grain, wastewater for slaughterhouse and other media.

Features of knife gate valves

- The sealing surface of the wedge can be lifted, which can scrape the stuff sticking to the sealing surface and automatically remove the sundries.

- The stainless steel wedge can prevent leakage caused by corrosion, and the fine grinding and polishing can obtain a better sealing effect.

- The stainless steel valve body is durable. The reinforcement design of the valve body improves the valve body’s strength, and the double-head screw is used to help with fast opening and closing.

- Precision casting is adopted for the valve body and packing box. The valve body is integrally casted. The material can be selected according to the requirements of the user. The sealing ring is made of PTFE-reinforced polytetrafluoroethylene, which is corrosion and wear resistance and has no slags.

- There is no slag and jamming for the circular direct channel.

- The scientific design of the upper seal stuffing box makes the upper have good sealing, which is effective and durable.

- A knife gate valve has a short structure length, which can save raw materials and have installation space, and also effectively support the pipeline.

- The triangular bracket saves raw materials and ensures the required mechanical properties.

- The guide block on the body of the knife gate valve makes the wedge move correctly. Extrusion blocks ensure effective sealing of the wedge.

- The valve plate has 5 supporting points. When the knife gate valve is closed and under back pressure, the valve plate will not move.

Parallel gate valves

Slab gate valves

Gate valves classified by stems

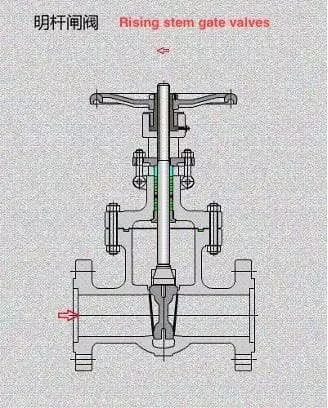

Rising stem gate valves

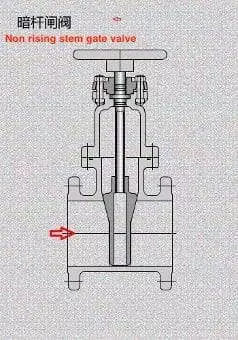

Non rising stem gate valves

Gate valves classified by bonnets

Welded bonnet gate valves

The valve body and bonnet of welded bonnet gate valves are connected by screw threads and are sealed by welding. Penetration welding can also be adopted if it is required by the customer. The socket-welded forged steel gate valve is designed with a reduced bore. Compared with the cast steel gate valve of the same diameter, the flow rate is slightly smaller, but the pressure and temperature range it withstands is higher than that of the cast steel valve; the sealing performance is much better than that of the cast steel gate valve and the service life is longer than that of the cast steel gate valve; the flow direction of the medium is not restricted like other gate valves.

Screw-in bonnet gate valves

Screw-in bonnet gate valves are very simple and can provide durable, pressure-resistant sealing.

Union bonnet gate valves

A union bonnet gate valve is a valve whose bonnet is held on by a union nut with threads on the body, which is used for places where regular inspection and cleaning are required. The nut is an optimum sized hexagon shaped with high tensile properties so that a leak-tight joint for maximum security under pressure can be provided.

Bolted bonnet gate valves

Bolted bonnet gate valves are used for large valves and higher pressure. The valve body and the bonnet are connected by bolts and nuts, and the wound gasket is used for sealing. The metal ring can also be used if there is a special requirement. The bolted bonnet cast steel gate valve can adapt to the deformation of the valve seat caused by thermal effects and the load of the connecting pipeline, which can ensure the reliability of sealing under low-pressure differential conditions, avoid the sticking or warping of the wedge and the valve seat under severe working conditions, and can be used in occasions with strict requirements for sealing and reliability of valves, such as high-pressure and high-temperature steam.

Pressure seal bonnet gate valves

Pressure seal bonnet gate valves are used for valves in high pressure, typically above 2250psi (15MPa). A unique feature of the pressure seal bonnet gate valve is that the end of the bonnet is a downward cup that fits into the valve body. As the pressure inside the valve increases, the sides of the cup are forced outward. Leakages tend to occur for other structures that provide sealing by external clamping pressure in the connecting part of the body and bonnet.

Gate valves classified by standards

Gate valves with American standards

Descriptions of gate valves with American standards

Design & Manufacture: API 600

Structure length: ANSI B16

Sizes of flanges: ANSI B16. 5a

Butt welding: ANSI B16. 25

Pressure and temperature: ANSI B16. 34

Test and Inspection: API 598

Features of gate valves with American standards

- The design and manufacture of the gate valve should meet the requirements of American National Standard ANSI B16.34, American Petroleum Institute Standard API 6D and API 600.

- Gate valves with American standards have a compact structure, small volume, good rigidity, safe and reliable sealing.

- The closing part (the wedge) adopts an elastic structure, which can automatically compensate for the deformation of the valve body caused by abnormal load or temperature during operation. Therefore, the sealing is reliable.

- The material of main bodies, internal materials, packing, gaskets and fasteners can be reasonably combined according to user requirements or actual working conditions.

- The valve seat can be a more lift-type valve seat, which can be combined and matched with the material of the closing sealing surface to meet the requirements of working conditions and prolong the service life.

Gate valves with German standards

Gate valves with German standards are usually made from cast iron, cast steel, stainless steel and alloy steel. DIN 3202-F4/F5/F7 gate valves with German standards are suitable for pipelines and equipment with liquid, gas and water, and are used for connecting or cutting off the medium. The fluid resistance of the valve and the torque required for opening and closing are small, and the flow direction is not restricted. The shape is relatively simple and the processability is good. Therefore, gate valves with German standards are widely used in food, medicine, water supply and drainage engineering, construction, fire protection and other fields.

Design standard: DIN 3352

Structure length: DIN 3202

Flange: DIN 2543-2545

Inspection: DIN 3230

Gate valves with Japanese standards

Gate valves with Japanese standards are suitable for various pipelines with pressure of Class150 to Class1500 or PN16 to PN100, which are used to cut off or connect the medium in the pipeline. Gate valves with Japanese standards made of different materials are applied to water, steam, oil, nitric acid, acetic acid, oxidizing medium, urea and other media. The driving mode is manual, gear transmission, pneumatic or electric modes. Gate valves with Japanese standards usually adopt flange ends, butt welding is also used.

Gate valves classified by connection ends

Flanged gate valves

A flanged gate valve is a gate valve connected by flanges, which is the most seen. Flanged gate valves are stable and reliable when used in pipelines, so they are often used in high-pressure pipelines.

Welded gate valves

A welded gate valve is a forced sealed valve with a simple structure, convenient manufacture and maintenance, small working stroke, fast opening and closing, good sealing, small friction force between the sealing surfaces, and long service life. The opening and closing part of the welded gate valve is a plug-shaped disc; a sealing surface is a plane or a conical surface, and the disc moves linearly along the center line of the fluid. Welded gate valve is a forced sealing valve. When the valve is closed, pressure must be applied to the valve disc to force the sealing surface not to leak. Welded gate valve is a forced sealing valve. When the valve is closed, pressure must be applied to the valve disc to force the sealing surface not to leak. The force to close the valve is greater than that to open the valve, so the diameter of the valve stem should be great. Otherwise, the bending of the top of the valve stem will occur. When the welded gate valve is opened, the opening height of the valve disc is 25% to 30% of the nominal diameter, the flow rate has reached the maximum, indicating that the valve has reached the fully open position.

Threaded gate valves

Threaded gate valves are valves whose valve bodies have internal screw threads or external screw threads, which are connected with pipelines by threaded ends. They are usually used for normal and low-pressure projects. Threaded gate valves are also divided into internally threaded gate valves and externally threaded gate valves.

Gate valves classified by pressure

High-pressure gate valves

High-pressure gate valves, also known as high-pressure power station gate valves, are mainly used in the pipelines of various systems in thermal power plants to cut off or connect the medium in the pipeline. High-pressure welded gate valves are suitable for non-corrosive media such as water and steam. High-pressure power station gate valves have features of high temperature, high pressure, and unique self-sealing compared with other valves. The higher the pressure is, the more reliable the sealing becomes. High-pressure gate valves also form characteristics that can’t be replaced by other valves due to their special performance and technical characteristics and special working conditions. The high-pressure welded gate valve should be installed horizontally.

Characteristics of high-pressure gate valves

- The shell adopts forging and casting, which has a smooth appearance and uniform structure, and meets the requirements of high temperature and high pressure.

- Special materials are used to ensure the high hardness of the sealing surface; the sealing surface is as smooth as a mirror, which is wear-resistant and corrosion-resistant, effectively prolonging the service life.

- The back seal design can effectively protect the sealing packing and prevent leakages.

- Multi-tests such as high-pressure water, high-pressure gas and non-destructive tests are performed to comprehensively control the quality of pressure-bearing parts.

- The surface of the valve stem is precisely ground and hardened, which is resistant to scratches and corrosion, effectively reducing the opening and closing torque and making the operation easier.

- A special corrosion-inhibiting packing structure is adopted, which is resistant to temperature and pressure, has no corrosion, and automatic lubrication, reduces opening and closing friction, avoids corrosion on the surface of the valve stem, and thus avoids external leakages.

- Two-way pressure-bearing sealing is adopted to meet the harsh requirements of various special working conditions.

- Strict manual grinding ensures that the goodness of fit of the double-sided sealing surface coincides is more than 90%.

- The valve bonnet is self-sealed. The higher the pressure is, the more reliable the sealing becomes.

Medium-pressure gate valves

Medium-pressure gate valves refer to gate valves that operate at a pressure between 1.6MPa and 4.0MPa.

Valve diameter: DN15 to DN1000

Nominal pressure: 1.6Mpa, 2.5 Mpa, 4.0 Mpa

Working temperatures: ≤425℃ ≤540℃ ≤600℃

Suitable medium: water, oil, steam, acidic medium, etc.

Materials: carbon steel, chrome molybdenum steel, chrome molybdenum vanadium steel and stainless steel

Drive modes: manual, worm gear, electric and pneumatic modes

Low-pressure gate valves

The low-pressure gate valve adopts flexible graphite packing and has a reliable sealing, easy and flexible operation. The drive mode includes manual, electric, pneumatic, and gear transmission modes. The low-pressure gate valve can be classified into elastic wedge single plates, rigid wedge single plates and double gates. The sealing surface of the low-pressure gate valve is made from stainless steel and hard alloy, which has a long service life.

Gate valves classified by driving modes

Electric gate valves

Electric gate valves are valves that are controlled by the electric actuator to realize the function of opening and closing. They are composed of upper and lower parts; the upper part is the electric actuator, and the lower part is the valve. The opening and closing speed of the electric gate valve can be adjusted; the structure is simple, and it is easy to maintain. During the operation, it is not easy to be damaged caused by jamming due to the buffering of the gas. However, there must be a gas source, and the control system is also more complicated than electric valves. Electric gate valves are sensitive to response, safe and reliable. The electric device is equipped with a torque control mechanism, a field operating mechanism and a hand-electric switching mechanism. In addition to on-site operation, remote operation, PLC control and intelligent control of 4 to 20mA current input and output are also available.

Pneumatic gate valves

Pneumatic gate valves are valves driven by compressed air. When the gate valve is closed, the sealing surface can be sealed only by the medium pressure, that is, relying on the medium pressure to press the sealing surface of the wedge to the valve seat on the other side to ensure the sealing of the sealing surface, which is self-sealing. Most gate valves are forcibly sealed, that is, when the valve is closed, the wedge must be forced against the valve seat by an external force to ensure the tightness of the sealing surface.

Manual gate valves

Manual valves are valves operated by manpower with the help of handwheels, handles, levers, and sprockets. When the valve’s opening and closing torque is great, a gear or worm gear reducer can be set between the handwheel and the valve stem. If necessary, the universal joint and drive shaft can also be used for remote operation. The manual valve is a control part in the pipeline fluid conveying system. It is used to change the passage section and the flow direction of the medium. It has the functions of diversion, cut-off, adjustment, throttling, preventing backflow, distributing flow and pressure relief.

Gate valves classified by materials

Stainless steel gate valves

Stainless steel gate valves are divided into stainless steel 304 gate valves and stainless steel 316 gate valves. The stainless steel 316 gate valve is used in sour water services, while the stainless steel 304 gate valve is used for general corrosive services, which are less corrosion resistant.

Carbon steel gate valves

A carbon steel gate valve is a kind of gate valve, its application is as follows:

The iron and steel industry: A carbon steel gate valve is used for coal, filter slurry in mining, iron and steel industry.

Purification devices: A carbon steel gate valve is used for waste water, mud, dirt and clear water with suspended solids.

Paper industry: A carbon steel gate valve is used for pulp with any concentration and material-water mixture.

Ash removal in the power station: A carbon steel gate valve is applied to the ash slurry.

After the carbon steel gate valve is welded with a cobalt-chromium-tungsten cemented carbide sealing surface, stress relief annealing should be carried out. For gate valves whose base is carbon steel, CoCrW cemented carbide, SF-4 (137) alloy, spray welding WF330 or Fe30 parts, the stress relief annealing heating temperature should be according to the base material, that is, carbon steel, generally between 600 to 650°C. The holding time depends on the effective thickness of the parts, generally 1h/25mm, at least 2 hours. After heat preservation, the furnace is cooled to 300℃ and then air-cooled.

Cast iron gate valves

Cast iron gate valves are mainly used in urban water supply and sewage treatment, which are soft-sealed and have good sealing performance.

Main features of cast iron gate valves

They are designed according to the AWWA C515 standard, which meet requirements for water supply. Full-bore design is adopted, which has the function of self-cleaning, large flow capacity and small pressure loss. They have reliable sealing, good appearance and anti-corrosion and long service life.

Specifications of cast iron gate valves

Drive modes: electric, pneumatic, manual and other modes

Nominal diameter: DN15 to DN600

Nominal pressure: PN10 to PN16, ANSI 150LB

Applicable temperature: 0 to 805°C

Applicable media: water, sewage, muddy water, etc.

Optional accessories: solenoid valves, positioners, limit switches, filter pressure-reducing valves, hand wheels, etc.

Copper (alloy) gate valves

Ends: flanged, threaded, loose nut, union body ends

Applications: used for drinking water or gas

Nominal sizes: DN 8 to DN 500

Pressure: PN 6 to PN 63 (Class 150 and Class 300)

Monel gate valves

The monel gate valve adopts the top-entry structure, which reduces the connecting bolts of the valve body under the condition of high pressure and large diameters, enhances the reliability of the valve and can overcome the influence of the weight of the system on the normal operation of the valve. Monel gate valves are widely used in coal chemical, petrochemical, rubber, paper, pharmaceutical and other pipelines.

Specifications of Monel gate valves

Nominal diameters: DN50mm to DN300mm

Nominal pressure: PN1.0MPa to1.6MPa

Temperature ranges: -29℃ to 300℃

Titanium alloy gate valves

Titanium and oxygen have a good affinity, and it is easy to react with oxygen to form a solid and dense passive oxide film on its surface. Therefore, titanium gate valves are widely used in transmission pipelines for corrosive media. Titanium gate valves are applied to the chlor-alkali, soda ash, pharmaceutical, fertilizer, fine chemical, textile fiber synthesis and bleaching and dyeing industry, basic organic acid and inorganic salt production, nitric acid industry and other industries, which bring significant economic benefits to these industries.

The main features of titanium alloy gate valves

Full bores or reduced bores

Bolted bonnets or welded bonnets

No self-tight sealing connections of flanges between the bonnet and the valve body

Renewable seats or body seats

The surface of the internal parts of titanium gate valves is hardened, so that a protective film is formed on the surface, which improves corrosion resistance, and also greatly improves the surface hardness, making the valve easy to be opened or closed and not easy to be scratched.

Ceramic gate valves

Ceramic gate valves refer to valves whose opening and closing part (the valve plate) is driven by the valve stem to move the sealing surface of the valve seat to move up and down, which can connect or cut off the fluid. When the valve is partially opened, an eddy current is generated on the back of the wedge, which is easy to cause erosion and vibration of the wedge, and also easy to damage the sealing surface of the valve seat, making the valve difficult to be repaired. The ceramic gate valve is characterized in that the surfacing cemented carbide sealing surface of the ordinary gate valve is replaced by a ceramic sealing surface component. The assembly consists of a ceramic sealing surface body, a locker and a sealing packing. Ceramic gate valves are wear-resistant, corrosion-resistant, high-temperature resistant, easy to maintain, and have a long service life, which are suitable for electric power, chemical industry, national defense, scientific research and other fields.

Plastic gate valves

The plastic gate valve consists of a plastic valve body, a valve bonnet, a valve stem, a valve plate, and a handwheel. The valve plate is located in the plastic valve body, and a valve seat matched with the valve is arranged in the plastic valve body. On the premise that the plastic gate valve still has a long service life, its manufacturing cost is greatly reduced.

Gate valves classified by manufacturing ways

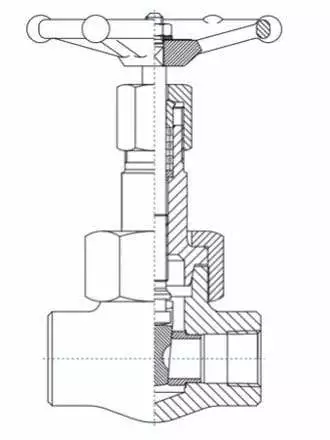

Forged steel gate valves

Forged steel gate valves are suitable for pipelines with small diameters of Class 150 to 2500 and operating temperatures of -29 to 425℃ (carbon steel) or -29 to 500 ℃ (stainless steel), which are widely used in petroleum pipelines.

Advantages of forged steel gate valves

Most of the forged steel gate valves have reduced bores. Compared with the cast steel gate valve of the same diameter, the flow rate of forged gate valves is slightly smaller, but its pressure and temperature range are higher than that of the cast steel valve; its sealing performance is also much better than that of the cast steel gate valve. Forged gate valves have a long service life. The forged steel gate valve has low fluid resistance, and its sealing surface is less scoured by the medium. The medium flow direction of the socket welded forged steel gate valve is not restricted.

Cast steel gate valves

Cast steel gate valves are gate valves that are made by casting. They can be divided into carbon steel gate valves, stainless steel gate valves, low alloy steel gate valves, and cryogenic gate valves based on the material.

Grades of cast steel gate valves commonly used are as follows:

1. The grades of carbon steel gate valve castings are WCA, WCB, WCC, LCB, etc., and the applicable temperature is -46 degrees to 425 degrees.

2. The grades of stainless steel gate valves are stainless steel 301, CF8 and CF8M, and the applicable temperature is -198 degrees to 816 degrees.

3. Low-alloy steel is divided into high-temperature alloy steel and high-strength low-alloy steel, among which high-temperature alloy steel is often referred to as chrome-molybdenum steel.

Grades of chrome molybdenum steel gate valves are ZG1Cr5Mo, ZG15Cr1MoV, ZG20CrMoV, WC6, WC9 and C12A. The applicable temperature is 550 degrees to 750 degrees.

The temperature applicable to each specific grade of material is different, depending on the actual working conditions.