Flex Wedge Gate Valve, GS-C25, 8 Inch, 600 LB, DN200, PN100

API 600 Cast Steel Gate Valve Supplier: API 600 Flex Wedge Gate Valves, OS & Y, GS-C25, Full Bore, 8 Inch, DN200, Class 600 LB, PN100, RF, FTJ, BW Ends.

Categories

- Gate Valves

Tags

- ISO Gate Valves , GOST Gate Valves , JIS Gate Valves

Detail Information

Full Bore GS C25 RF Flanged Cast Steel Gate Valve

Name: Casting Steel 200mm Gate Valve

Material: Cast Steel

Connection: RF Flange, RTJ Flange, BW

Standard: API 600, API 603, DIN, JIS, GOST, ISO

Size: 8 Inch, DN200

Pressure: Class 600 LB, PN100

Power: Manual, Pneumatic, Solenoid, Electrical Actuated

Temperature Of Media: Medium Temperature, Normal Temperature, High Temperature, -65℉ - 450℉ (-54℃ - 232℃)

High Light: Full Bore, GS C25 flexible wedge type, OS & Y

Product Range

Size: 2 - 48 Inch, DN50-DN1200

Pressure: Class 150-2500 LB

Feature

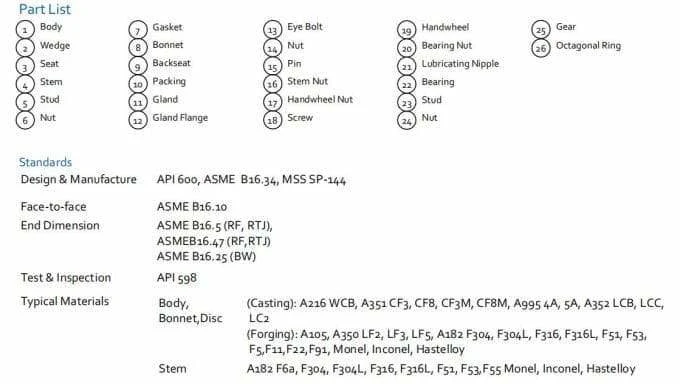

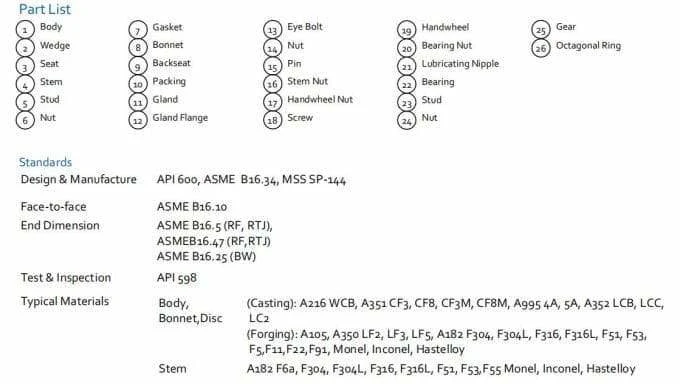

1. Bolted bonnet, pressure bonnet, bellow seal bonnet, high/low temperature extended bonnet and ISO 15848 fugitive emission designed valves are available upon different request of services.

2. Forged body can also be provided upon special request.

3. Unlike forging, casting uses the liquid form of metal to create valves. These metals are melted into a molten liquid and poured into various molds. One of the biggest benefits of casting is that it can create valves with complex shapes, patterns, and sizes. Using a mold to manufacture these devices gives you more freedom to make different types of valves with more intricate parts.

Name: Casting Steel 200mm Gate Valve

Material: Cast Steel

Connection: RF Flange, RTJ Flange, BW

Standard: API 600, API 603, DIN, JIS, GOST, ISO

Size: 8 Inch, DN200

Pressure: Class 600 LB, PN100

Power: Manual, Pneumatic, Solenoid, Electrical Actuated

Temperature Of Media: Medium Temperature, Normal Temperature, High Temperature, -65℉ - 450℉ (-54℃ - 232℃)

High Light: Full Bore, GS C25 flexible wedge type, OS & Y

Product Range

Size: 2 - 48 Inch, DN50-DN1200

Pressure: Class 150-2500 LB

Feature

1. Bolted bonnet, pressure bonnet, bellow seal bonnet, high/low temperature extended bonnet and ISO 15848 fugitive emission designed valves are available upon different request of services.

2. Forged body can also be provided upon special request.

3. Unlike forging, casting uses the liquid form of metal to create valves. These metals are melted into a molten liquid and poured into various molds. One of the biggest benefits of casting is that it can create valves with complex shapes, patterns, and sizes. Using a mold to manufacture these devices gives you more freedom to make different types of valves with more intricate parts.

| ASME CLASS 600 (PN 100) | |||||||

| Size | D | L | H | W | Weight RF/BW |

||

| in/mm | RF | RTJ | BW | (lb/kg) | |||

| 2 50 |

2 51 |

11.5 292 |

11.63 295 |

11.5 292 |

16.5 418 |

441 200 |

79/64 36/29 |

| 2 ½ 65 |

2.5 64 |

13 330 |

13.13 333 |

13 330 |

18.75 476 |

551 250 |

115/93 52/42 |

| 3 80 |

3 76 |

14 356 |

14.13 359 |

14 356 |

20.38 518 |

617 280 |

148/117 67/53 |

| 4 100 |

4 100 |

17 432 |

17.13 435 |

17 432 |

25.5 646 |

661 300 |

247/183 112/83 |

| 5 125 |

5 125 |

20 508 |

2012 511 |

20 508 |

29.5 750 |

881 400 |

330/267 150/121 |

| 6 150 |

6 150 |

22 559 |

22.13 562 |

22 559 |

33 840 |

991 450 |

374/275 170/125 |

| 8 200 |

7.87 200 |

26 660 |

26.13 663 |

26 660 |

40.38 1025 |

1100 500 |

866/683 393/310 |

| 10 250 |

9.76 248 |

31 787 |

31.13 790 |

31 787 |

48.38 1230 |

23.62 600 |

1344/1040 610/472 |

| 12 300 |

11.73 298 |

33 838 |

33.13 841 |

33 635 |

57 1450 |

23.62 600 |

1960/1608 890/730 |

| 14 350 |

12.87 327 |

35 889 |

35.12 891 |

35 889 |

62 1575 |

- | 2742/2324 1245/1055 |

| 16 400 |

14.76 375 |

39 991 |

39.13 994 |

39 991 |

70.62 1795 |

- | 3370/2731 1530/1240 |

| 18 450 |

16.5 419 |

43 1092 |

43.13 1095 |

430 1092 |

76 1930 |

- | 4317/2786 1960/1625 |

| 20 500 |

18.27 464 |

47 1194 |

47.25 1200 |

47 1194 |

87 2210 |

- | 5396/4471 2450/2030 |

| 22 550 |

20.12 511 |

51 1295 |

51.38 1305 |

51 1295 |

97.24 2470 |

- | 6123/4956 2780/2250 |

| 24 600 |

22 559 |

55 1397 |

55.38 1407 |

55 1397 |

101.5 2580 |

- | 6597/5705 2995/2590 |

| 26 650 |

23.74 603 |

57 1448 |

57.5 1461 |

57 1448 |

105 2665 |

- | 7654/6289 3475/2855 |

| 28 700 |

25.51 648 |

61 1549 |

61.5 1562 |

61 1594 |

109.5 2780 |

- | 8205/6751 3725/3065 |

| 30 750 |

27.36 695 |

65 1651 |

65.5 1664 |

65 1651 |

114 2895 |

- | 8910/7489 4045/3400 |

Next: Carbon Steel Through Conduit Gate Valve, 4 Inch, 900 LB

Previous: API 6A Wellhead Gate Valve, RTJ, 10000 PSI, DN46-DN230