Selección de Materiales y Componentes de Válvulas de Macho

Aug 14, 2023

Dado que las condiciones de funcionamiento son de alta temperatura y alta presión, y el medio es ácido fluorhídrico altamente corrosivo y tóxico. Para mejorar la resistencia a la corrosión de la válvula y, al mismo tiempo, considerar la eficiencia económica del equipo, la válvula macho debe fabricarse en su totalidad con una aleación de Ni-Cu. La aleación Ni-Cu es resistente a la corrosión en ácido fluorhídrico en todas las concentraciones y temperaturas, es decir, su estabilidad es sobresaliente y se ve menos afectada por el caudal. Por lo tanto, las bombas,válvulasy otros equipos y piezas en condiciones de alto caudal utilizan aleaciones de Ni-Cu que son más adecuadas. En el sistema de unidad de alquilación HF, la aleación puede cumplir con los requisitos de diseño y lograr un efecto de protección laboral relativamente confiable. El cuerpo de la válvula, el casquete y el obturador de la válvula de aleación Ni-Cu integral están hechos de aleación Ni-Cu fundida de grado HS-1, y su composición química (%) y propiedades mecánicas se muestran en la Tabla 5.

El casquete, el diafragma metálico y el prensaestopas están hechos de aleación de Ni-Cu, la junta de grafito flexible y el diafragma de sellado de PTEE o F46.

Tabla 5 Composición química y propiedades mecánicas del HS-1

El casquete, el diafragma metálico y el prensaestopas están hechos de aleación de Ni-Cu, la junta de grafito flexible y el diafragma de sellado de PTEE o F46.

Tabla 5 Composición química y propiedades mecánicas del HS-1

| Chemical composition | Ni | Co | Cr | Mo | Fe | C | Si | Mn | W | Cu | Others |

| Quality score, % | 67 | - | - | - | 1.4 | 0.15 | - | - | - | 30 | 1.45 |

| Tensile strength | Yield strength | Elongation rates | Hardness HBW | ||||||||

| 600 to 880 | 390 to 840 | 10 to 35 | 160 to 250 | ||||||||

4. Sealing of plug valves

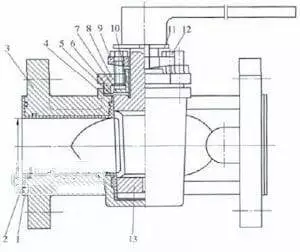

In the HF alkylation unit, because the liquefied petroleum gas is flammable and explosive, and the catalyst HF is highly corrosive and toxic, the requirements for labor protection are relatively high. Therefore, the requirement for sealing the plug valve is relatively high. To improve the sealing performance, The traditional plug valve has been improved, as shown in Figure 4.

1. Spiral wound gaskets 2. Sealing bushing 3. Valve bodies 4. Gaskets 5. Sealing diaphragms 6. Metal diaphragms 7. Packing sleeves 8. Valve bonnets 9. Adjusting discs 10. Packing 11. Positioning plates 12. Bolts 13. Valve plugs

Figure 4 Structural diagram of plug valves

The sealing mechanism is as follows: a special PFA sealing bushing is pressed into the inside and end of the entire cock cavity, and the inverted trapezoidal groove on the valve body and the cock is well fitted with the sealing sleeve to achieve a good sealing effect. The valve stem and the plug body are of an integral structure, which simplifies the manufacturing process. As shown in Figure 4, the lower part of the valve stem’s sealing device is a flexible graphite gasket, and there is a PTEE or F46 sealing diaphragm on it; the top is covered with a Ni-Cu alloy metal diaphragm. Cu alloy metal diaphragm, PTEE or F46 sealing diaphragm and flexible graphite gasket are pressed well with the valve body to prevent HF from leaking through the valve body. There is also a packing gland on the valve stem, and a circle of flexible graphite packing is installed on the lower part of the gland, which is pressed well by bolts. On the one hand, the packing is squeezed on the valve stem, and on the other hand, the above two diaphragms and gaskets are pressed into the deep groove where the plug connects to the stem to form a reverse lip seal. This kind of seal can play a self-sealing role by means of the pressure inside the valve, which can effectively prevent the leakage of HF. In addition, the flexible graphite filler and gasket in the sealing device can prevent the medium in the valve from leaking into the atmosphere in case of fire. The connection between the valve body and the pipe is also a place where the leakage is likely to occur, so it should also be sealed. The end face is connected to the pipeline with a flange due to the large size of the valve body, and the outer periphery of the sealing bush is sealed with a metal spiral wound gasket, which further strengthens the seal.

Conclusion

1) The seal at the valve stem of this plug valve is safer and more reliable, and the integral bushing in the valve effectively prevents internal leakage and reduces process losses. Compared with ordinary plug valves, this valve has good sealing performance and corrosion resistance, and has fire protection, small opening and closing torque, and can meet the requirements for the production of the alkylation unit.

2) The results of ANSYS analysis show that the main stress concentration part of the valve body is the connection between the valve cylinder and the channel, which provides a reliable basis for the design of the valve and the casting production process. During design, pay attention to reducing the stress concentration here, and the thickness should be appropriately increased to reduce the possibility of failure.

3) The overall bushing inside the valve wastes material. To make the bushing fit better on the inner wall of the valve, it is necessary to process several process grooves inside the valve body, which increases the processing technology.

Anterior: Diseño de Válvulas de Tapón en la Unidad de Alquilación de Refinería

Siguiente: Válvulas utilizadas para la industria química del carbón