ASTM A351 CF8 Diaphragm Valve, 1 Inch, 150 LB, RF Flanged

ASTM A351 CF8 Diaphragm Valve Fabricator: Stainless Steel Pneumatic Diaphragm Valves, ASTM A351 CF8+F46, DN25, 1 Inch, PN10, 150 LB, GB 12239-89, RF Flanged.

Categories

- Globe Valves

Tags

- 1 Inch Globe Valve , DN25 Globe Valve , Class 150 LB Globe Valve

Detail Information

ASTM A351 CF8 Stainless Steel Pneumatic Diaphragm Valve

Design Standard: GB12239-89

Body Material: ASTM A351 CF8+F46, Stainless Steel

Disc Material ASTM A351 CF8

Diaphragm Material F46+NR

Nominal Diameter: DN25, 1 Inch

Pressure: PN10, Class 150 LB

End Connection: RF Flange

Temp. Range ≤150℃

Face To Face: JB1688

Test And Inspection: API 598

Feature: Pneumatic Diaphragm Valve

Type: Diaphragm valve

Construction Bolted Bonnet, Fluorine Lining Trim

Connection: RF

F to F Dimension JB1688

Flange Dimension GB 4216.4/HG 20592

Test & Inspection GB/T 13927

Media: Corrosive Media

Weir-type diaphragm valves:

The weir-type diaphragm valve is one of the most common designs available. The raised lip/saddle design is best suited for small flow control and is kept leak-proof thanks to the bonnet over the diaphragm and actuator. This design is optimal for dangerous or corrosive liquid and gas, as any failure with the membrane will be kept contained by this bonnet.

Diaphragm Valves Information

Diaphragm valves get their name from a flexible disc that comes into contact with a seat at the top of the valve body to form a seal. A diaphragm is a flexible, pressure-responsive element that transmits force to open, close or control a valve. Diaphragm valves are related to pinch valves, but use an elastomeric diaphragm, instead of an elastomeric liner in the valve body, to separate the flow stream from the closure element.

Diaphragm Valve Function

The diaphragm is connected to a compressor by a stud molded into the diaphragm. The compressor is moved up by the valve stem to start or increase flow. To stop or slow flow, the compressor is lowered and the diaphragm is pressed against the bottom of the valve. Diaphragm valves are excellent for controlling the flow of fluids containing suspended solids and offer the flexibility of being installed in any position. Weir-type diaphragm valves are better at throttling than straight-through diaphragm valves because the design's large shutoff area along the seat gives it the characteristics of a quick-opening valve. The diaphragm acts as the gasket of the valve to seal against leaks between the body and bonnet cap.

The straight-through type can be used in situations where the flow direction changes within the system. The body of this design has a flat bottom that is parallel to the flow stream. This allows the flow to move uninhibited through the valve with no major obstructions. The flexible material is required for the diaphragm so that the machine can reach the bottom of the valve body; this can shorten the life span of the diaphragm. They are excellent for use with sludge, slurries and other viscous fluids but they are not well suited for high-temperature fluids.

Design Standard: GB12239-89

Body Material: ASTM A351 CF8+F46, Stainless Steel

Disc Material ASTM A351 CF8

Diaphragm Material F46+NR

Nominal Diameter: DN25, 1 Inch

Pressure: PN10, Class 150 LB

End Connection: RF Flange

Temp. Range ≤150℃

Face To Face: JB1688

Test And Inspection: API 598

Feature: Pneumatic Diaphragm Valve

Type: Diaphragm valve

Construction Bolted Bonnet, Fluorine Lining Trim

Connection: RF

F to F Dimension JB1688

Flange Dimension GB 4216.4/HG 20592

Test & Inspection GB/T 13927

Media: Corrosive Media

Weir-type diaphragm valves:

The weir-type diaphragm valve is one of the most common designs available. The raised lip/saddle design is best suited for small flow control and is kept leak-proof thanks to the bonnet over the diaphragm and actuator. This design is optimal for dangerous or corrosive liquid and gas, as any failure with the membrane will be kept contained by this bonnet.

Diaphragm Valves Information

Diaphragm valves get their name from a flexible disc that comes into contact with a seat at the top of the valve body to form a seal. A diaphragm is a flexible, pressure-responsive element that transmits force to open, close or control a valve. Diaphragm valves are related to pinch valves, but use an elastomeric diaphragm, instead of an elastomeric liner in the valve body, to separate the flow stream from the closure element.

Diaphragm Valve Function

The diaphragm is connected to a compressor by a stud molded into the diaphragm. The compressor is moved up by the valve stem to start or increase flow. To stop or slow flow, the compressor is lowered and the diaphragm is pressed against the bottom of the valve. Diaphragm valves are excellent for controlling the flow of fluids containing suspended solids and offer the flexibility of being installed in any position. Weir-type diaphragm valves are better at throttling than straight-through diaphragm valves because the design's large shutoff area along the seat gives it the characteristics of a quick-opening valve. The diaphragm acts as the gasket of the valve to seal against leaks between the body and bonnet cap.

The straight-through type can be used in situations where the flow direction changes within the system. The body of this design has a flat bottom that is parallel to the flow stream. This allows the flow to move uninhibited through the valve with no major obstructions. The flexible material is required for the diaphragm so that the machine can reach the bottom of the valve body; this can shorten the life span of the diaphragm. They are excellent for use with sludge, slurries and other viscous fluids but they are not well suited for high-temperature fluids.

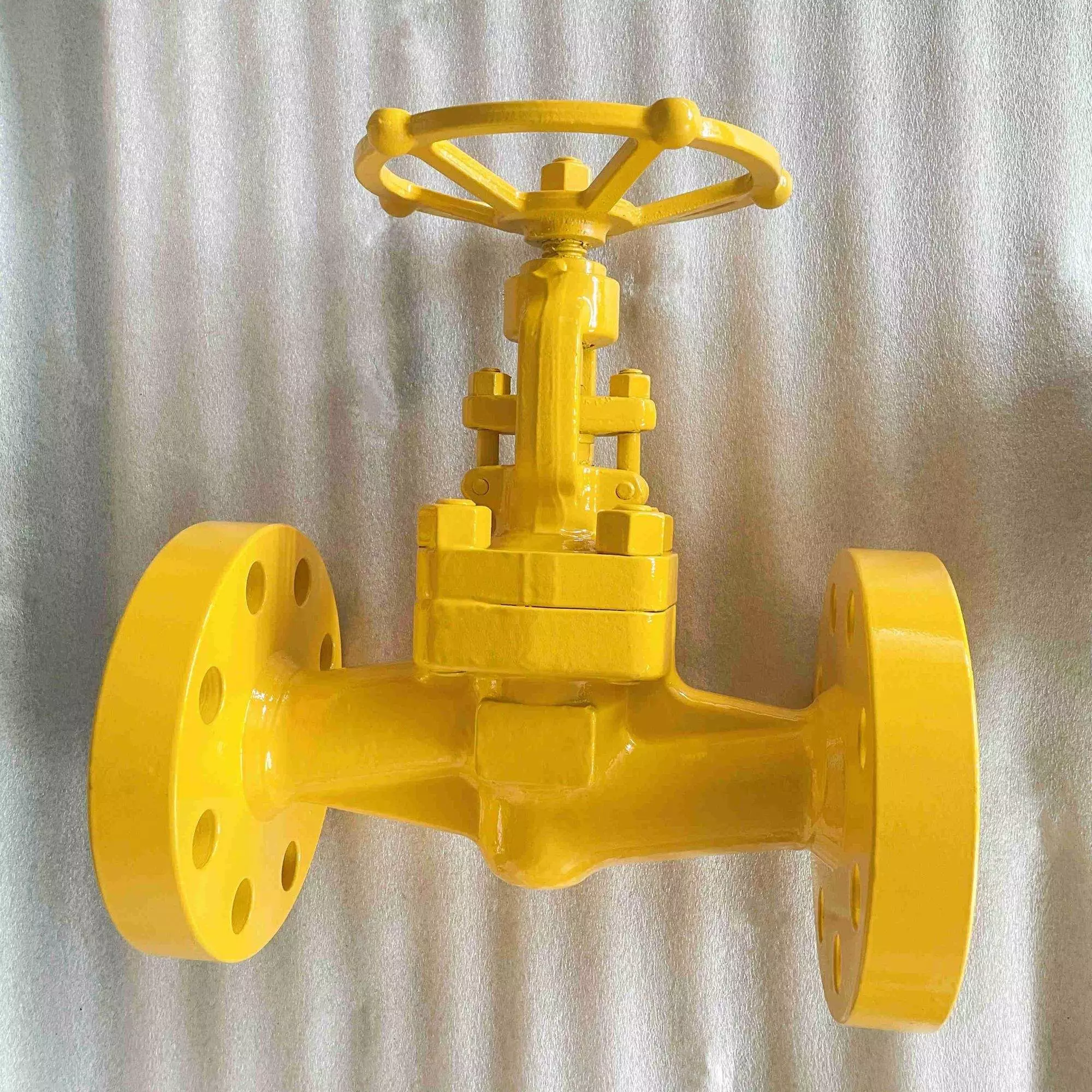

Next: ASTM A216 WCB Y Globe Valve, 10 Inch, 1500 LB, API 600, BW

Previous: Power Station Stop Globe Valve, 3/8 Inch, 2500 LB, BW